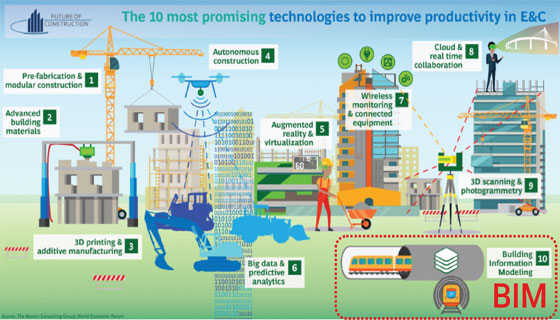

BIM Brings great benefits, says Dodge Analytics Survey

Tweet

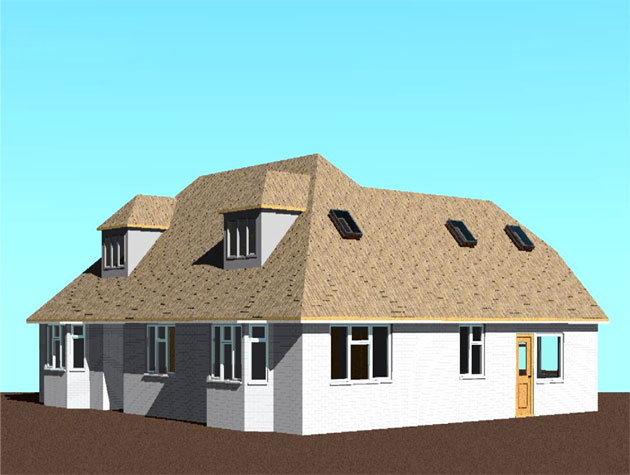

Another investigation of mechanical and HVAC contractors utilizing Building Information Modeling software (BIM) uncovers how much these contractors are locked in with BIM, the advantages that they experience from its utilization, and the difficulties they face in extending the utilization of BIM.

The overview shows that mechanical contractors are advanced clients of BIM software who have seen the advantages from that utilization.

In any case, the investigation additionally shows that the capacity of these contractors to completely use the benefit of modeling innovations is hampered via preparation and labor issues, alongside the test of getting other undertaking partners similarly occupied with BIM.

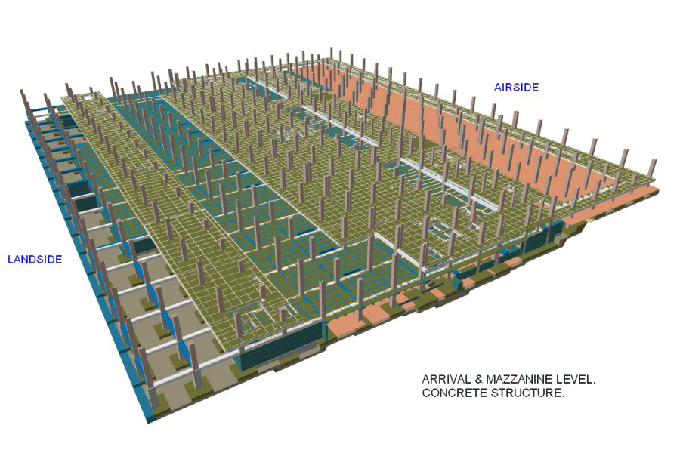

As indicated by Scott Pittman, Vice President of Pinnacle Infotech Inc, virtual development has made some amazing progress in an exceptionally brief timeframe. The times of the chalk line and paper archives are diminishing, and we are seeing more laser scanners and layout apparatuses to help with particular development and pre-produced congregations.

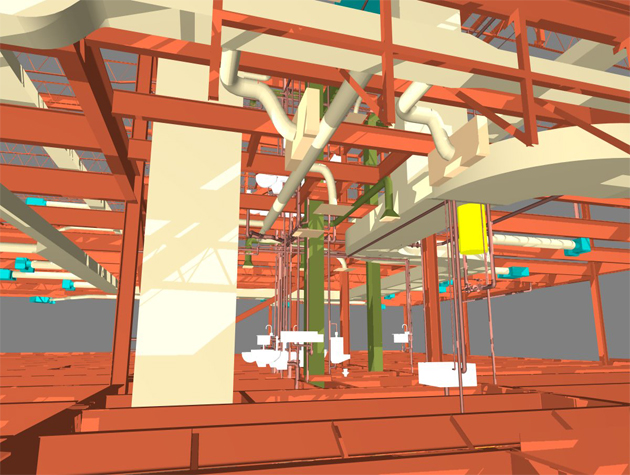

Probably the greatest advantage announced by contractors is the capacity of BIM to improve the fabrication procedure.

Numerous mechanical contractors visit clients of offsite fabrication for their frameworks, and the investigation shows that almost half use BIM on half or a greater amount of the congregations they pre-assemble.

This is exhibiting that BIM is a basic apparatus for this procedure. Advantages from utilizing BIM to help prefabrication are generally detailed, with over 80% of mechanical contractors who use it to pre-assemble.

This reveals that they see upgrades in the material waste created, work costs, nature of introduced work, maintaining a strategic distance from the acquisition of additional funnels and fittings and timetable execution.

It used to be that having the range of abilities that was expected to do the geometry and calculations to perform prefabrication without full drawings was conceivable. Presently, when utilizing the BIM models, there is anything but an extraordinary point of view engaged with the fabrication.

There is on the specifying and drawing side, yet on the shop fabrication side, they're given accurate connections and measurements. It evacuates the requirement for that estimation range of abilities, and fabrication turns into a normal shop procedure of cutting, gathering and introducing, as opposed to controlling the numbers.

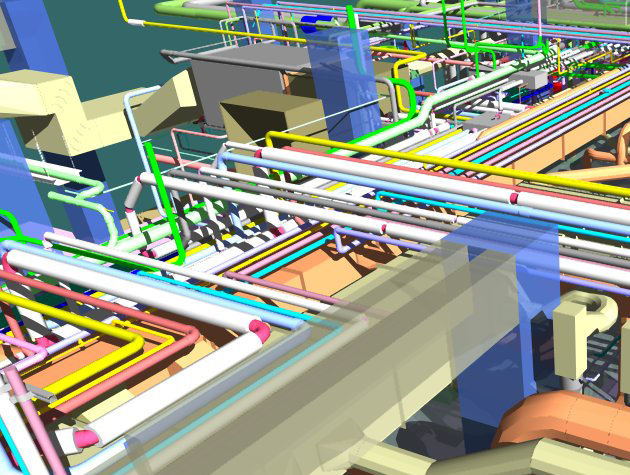

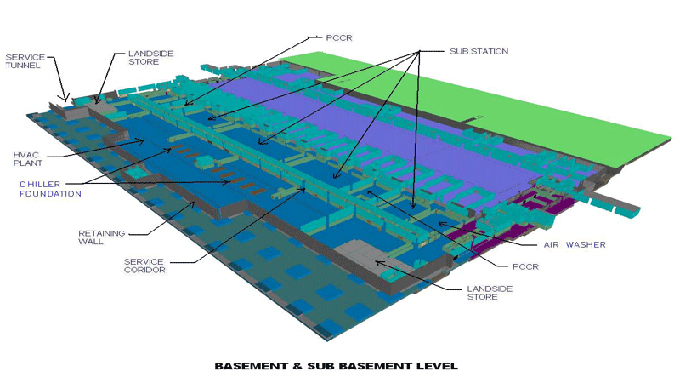

By utilizing BIM, mechanical contractors have additionally had the option to use the innovation to lead more examination on their undertakings. Over 70% report that they use BIM for shop drawings and spatial coordination on half or a greater amount of their activities. Almost 66% (61%) report utilizing BIM for constructability assessment on the greater part of their undertakings.

As indicated by Steve Jones, Senior Director of Industry Insights at Dodge Data and Analytics, utilization of BIM for spatial coordination and constructability assessment gives these contractors an unmistakable bit of leeway.

They can address issues before development starts, which sets aside both time and cash, and can even assist in improving security by staying away from adjustment.

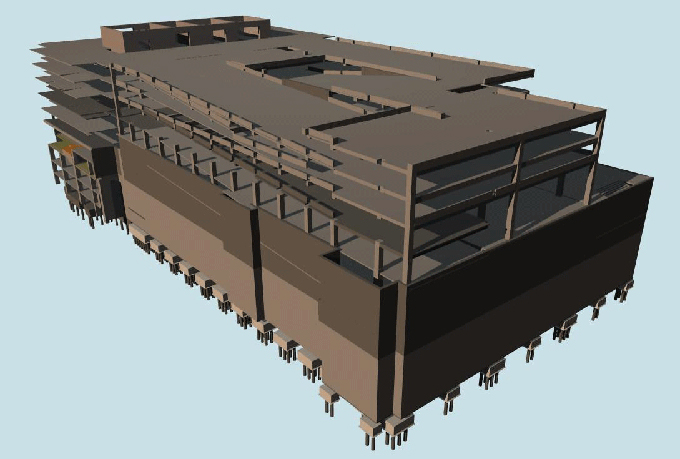

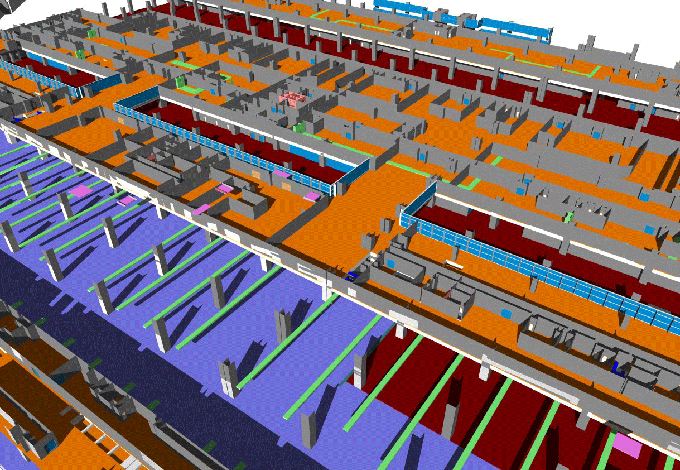

The study uncovered difficulties that keep these contractors from completely utilizing the utilization of BIM. The greatest difficulties incorporate preparing requirements for workers and absence of accessible labor to make BIM models.

Likewise, these contractors battle with full commitment with BIM over the venture group, with absence of help for BIM from other significant exchanges, the issue of different partners on their tasks not utilizing BIM, and low quality BIM use by different partners additionally introducing noteworthy difficulties.

Tending to these issues will permit much more contractors to all the more completely experience the advantages of utilizing BIM cooperatively on their undertakings.

There are numerous factors in each development procedure, including the general contractual worker, the climate, and the individuals at work. With such huge numbers of factors outside of your control, it's difficult to really gauge efficiency and the increments.

The BIM procedure requires direct front exertion and direct front arranging. That degree of pre-arranging and contribution brings rewards when you secure less positions and turn out badly.

We realize that on the off chance that we can stretch out beyond that bend, we have better command over what will occur on the task. The BIM procedure stretches us further beyond in light of the fact that we're doing things prior.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !