What is the benefit of using the latest technology like BIM in Wastewater?

Tweet

Asset management becomes more efficient when you combine wastewater treatment with the latest technologies like BIM, SCADA, PLC, & drones. It is important for the human health & environment while having water & wastewater treatment.

Technology Integration

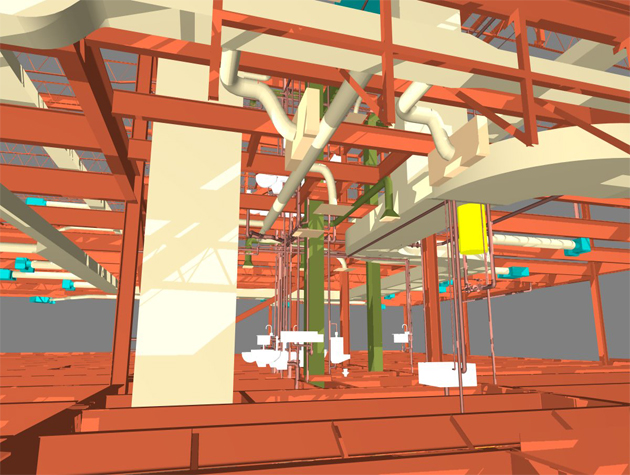

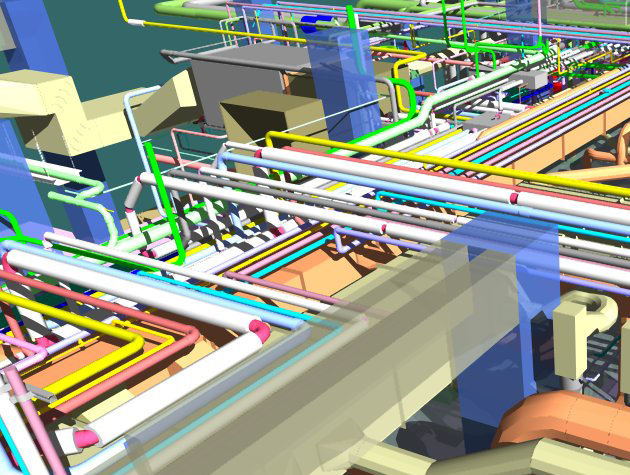

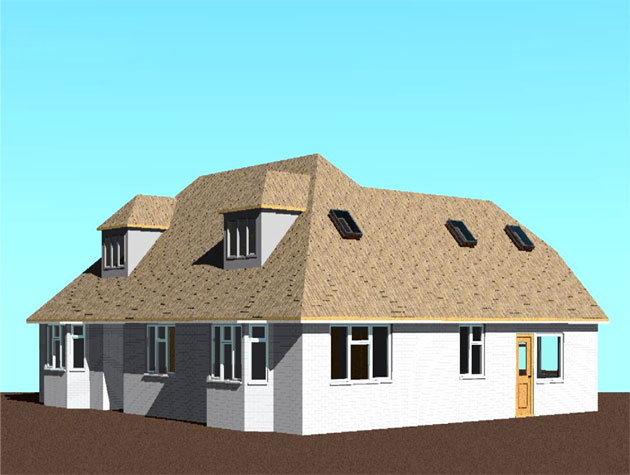

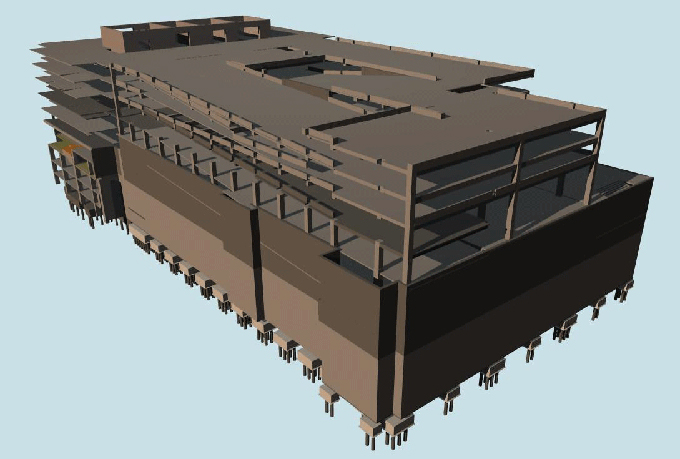

Building Information Modeling (BIM)

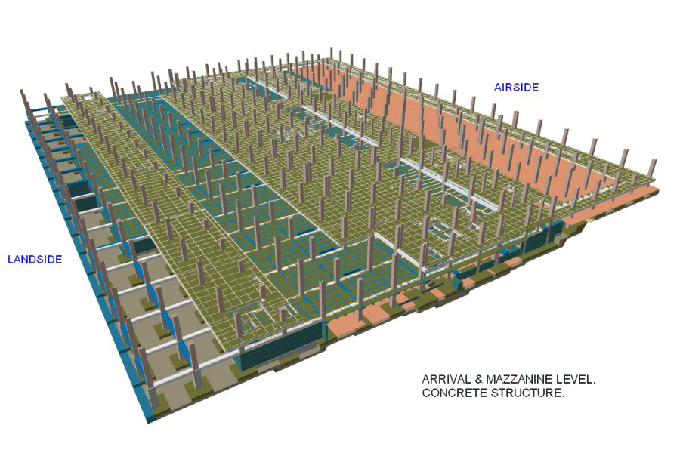

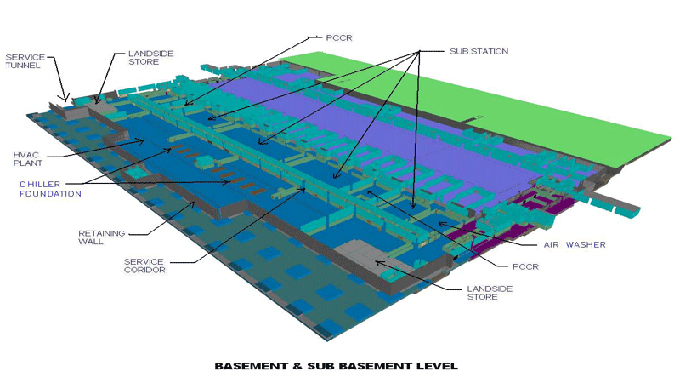

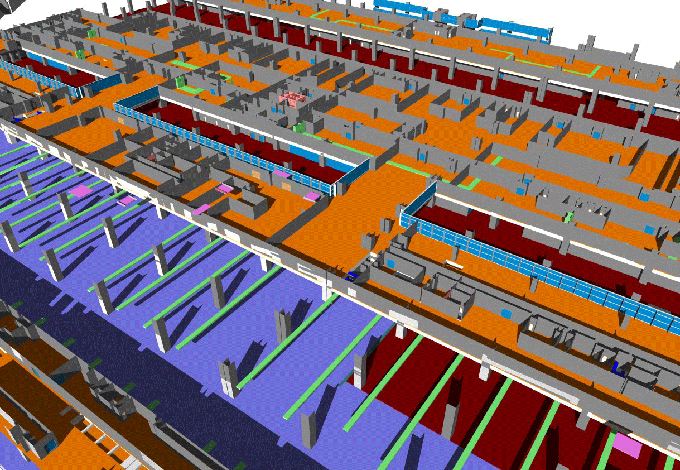

Infrastructure projects around the world are taking advantage of advanced technologies such as Building Information Modeling or BIM. There is acceleration in the implementation of BIM for water projects. Using BIM improves water projects with a higher level of client satisfaction.

A BIM model improves the design and development of a project. In the water sector, Dodge Data research reveals that multi-party collaboration results in reduced errors and conflicts and better communication through 3D visualization because of BIM.

When users realize how BIM supports the entire facility lifecycle, they are more likely to mandate its use and gain an advantage over the competition. Using BIM will enable engineers and contractors to improve project delivery and owners to manage assets and operations more effectively.

Supervisory Control & Data Acquisition Systems (SCADA)

Wastewater treatment plants also benefit from supervisory control and data acquisition systems. It is standard practice to use SCADA systems, and updating to cloud based SCADA systems can improve reliability and efficiency.

In water management plants, chemical and toxin levels can be monitored with a cloud based supervisory control and data acquisition system. In addition to providing precise records, the SCADA system also facilitates easy access to those records from anywhere. From any satellite or WIFI-enabled device, managers or operators can access data anytime.

Data collected from polluted areas in real-time can be compared, studied, and shared with investigators quickly and efficiently using a cloud based SCADA system. A thorough analysis of the data points will lead to the best information, and that will in turn lead to more rapid action by investigators.

Programmable Logic Controllers (PLC) Using Human Machine Interference (HMI)

A Human Machine Interface is used in conjunction with Programmable Logic Controllers to operate Water Treatment Plants. Installing the PLC and HMI system can be accomplished by wastewater treatment managers, ensuring minimal downtime.

Monitoring wastewater treatment systems with innovative Human Machine Interface Systems is effective. Chemical & engineering decisions can be made by PLCs to optimize treatment. HMI systems typically include graphical controls for monitoring all aspects of water treatment systems, including chemical usage, system history, pH, tank levels, and alarms.

Displaying information on a high resolution touchpad screen makes monitoring the system easy.

Drone

With drones, costs can be reduced, operational efficiency can be improved, and clean water can be delivered more efficiently. In order for water treatment facilities to provide freshwater to their municipalities, they have to deal with energy consumption, overhead costs, and infrastructure failures.

By using drones, plant managers can collect visual information that can help them identify energy-saving opportunities, like areas losing water and modify the area to improve infiltration of storm water.

There are various useful ways to use drones for managing wastewater treatment requirements in the wastewater treatment sector & analysts making projections.

Workers Safety

A task that involves inspection can be time consuming and hazardous for humans, taking teams of people several days to complete. In a wastewater plant, drones can increase worker safety. When using a drone, a similar job takes only a couple of minutes and requires the least amount of workers.

Water Testing

Water testing is vital to operating wastewater treatment plants as the drone improves the process.

Without testing, the plant representatives would have unknown if their systems are delivering the results they want. A drone can be equipped with sensors so that plant managers can conduct water tests in an advanced manner. Water can be tested in hazardous areas, such as oil spills, where humans can be injured. The drone can also collect pH, conductivity, and temperature data at a specific location.

To get online demonstration, watch the following video tutorial.

Video Source: VinZero - Capricot Technologies

Problem Inspection

Water treatment plants can also use drones to inspect isolated areas of the plant for cracks and other problems.

It is possible to capture high quality footage with drones in a short amount of time. In the event of a gas leak or infrastructure breakdown, maintenance managers can detect severe problems. As a result, they decide where to allocate resources and take the necessary action before disaster strikes.

Aerial photographs and videos taken by drones can provide water plant managers with previously unknown, in-depth information. The information makes site inspections more efficient and affordable while utilizing technologies like 3D mapping.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !