Top 5 Trends to watch out for 3D printing in 2023

Tweet

Due to uncertainty over fuel and production costs, manufacturing industries around the world have faced a challenging three years. In spite of these challenges, Additive Manufacturing has helped manufacturers overcome supply chain disruptions and develop stronger, lighter, and fewer-part products.

As well as promoting eco friendly practices in manufacturing, it reduces environmental impact and allows for the repurposing of waste materials. 3D printing can be used to create products that are environmentally friendly as well as highly customized.

Once rigorously tested & approved for the end product, 3D printing can be used for sustainable materials in production. Circular economies can be achieved by 3D printing materials sourced from construction waste.

Define 3D Printing

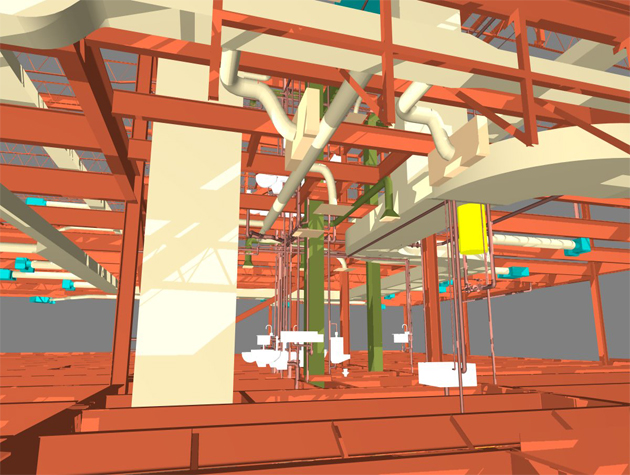

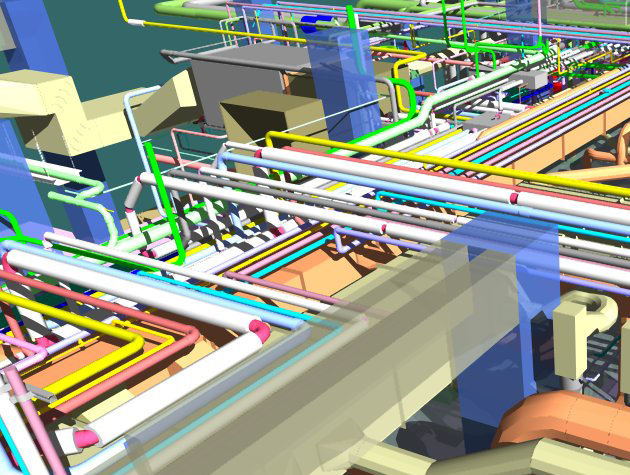

By building up layers at a time, 3D printing converts digital 3D models into physical objects. Since its invention in the 1980s, 3D printing has become increasingly integrated into everyday life, especially in the field of architecture and interior design.

Before sending the model to the printer, the modeling process or 3D design must receive proper attention. It is important to select the appropriate material composition after finalizing the design.3D printing for interior design requires cement, signs, rubber, sand, and plastic.

Latest Trends for 3D Printing

Productivity & Reliability

There are two main groups of users in Additive Manufacturing: Advanced users who want increased performance and reliability from their printers. Those who believe Additive Manufacturing can be beneficial but need guidance on how to deploy it and overcome their manufacturing status quo.

Application Driven Production

Factory concepts that are application driven will gain more traction in the future. You can optimize industrial 3D printers, peripherals, and post processing to maximize throughput and minimize costs.

Additive Manufacturing optimization can transform an unviable business case into a feasible scenario or increase profits & design innovation possibilities. The optimized solution would be available only for some combinations of 3D printing applications.

Innovating Hybrid Materials

As hybrid 3D printing materials become available, they will meet the needs of different industries by being designed and engineered uniquely. At different points in the additive build process, process parameters can be adjusted to alter material characteristics such as ductility and tensile strength.

Sustainability

Several years ago, manufacturers and brands began using sustainability as a way to lessen their impact on the environment. In recent years, the industry has taken steps towards reducing energy consumption and manufacturing waste as well as gradually eliminating non recyclable materials from products. Products and services must now demonstrate their sustainability credentials before they can be sold.

Digital Thread

Manufacturing can now manage products from concept to end of life more efficiently with Additive Manufacturing, which connects the physical and digital supply chains. With a digital manufacturing system in place, manufacturing can be distributed across any location by simply sending a file.

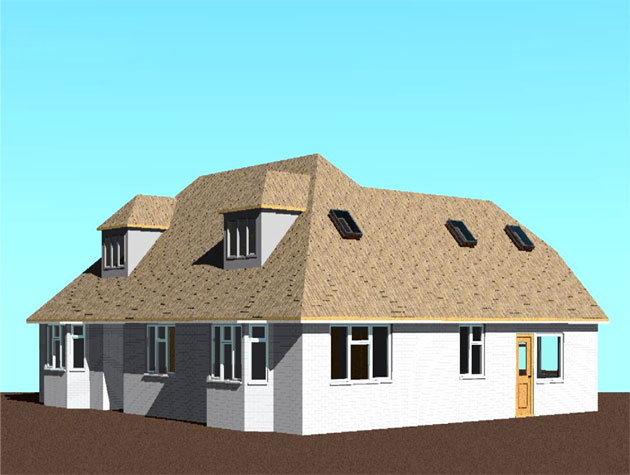

3D Printing Application

Despite its popularity in industries like aerospace, military, and manufacturing, 3D printing has found its way into home decor and furnishings because of its affordability and success. There is an increasing availability of custom interior products, including 3D printed items. Several retailers and manufacturers offer customers the option to design 3D printed home furnishings or other items tailored to their needs.

While traditional custom manufacturing methods are still used, people are turning to 3D printing and personalized furnishings for their homes as a way to distinguish their homes from others.

Customization has been made possible by 3D printing, allowing for the design and creation of intricate, one-of-a-kind home furnishings that cater to individual tastes and preferences.

3D Printing Benefits

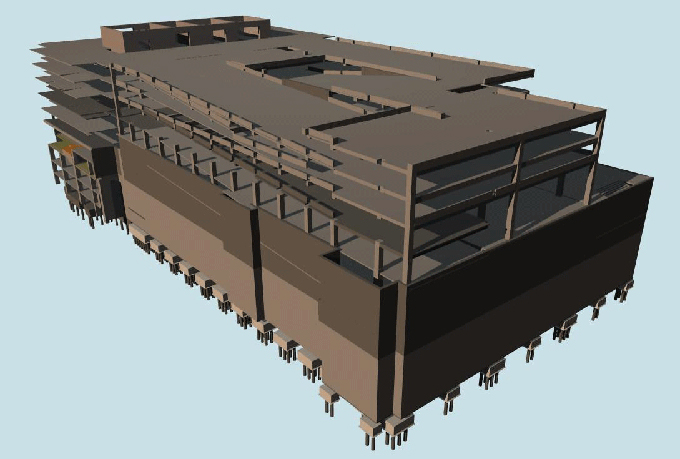

For each project, clients have a wide range of options in the interior design industry. It is difficult for interior design firms to differentiate themselves from competitors in such a dynamic environment. In order to achieve success and secure future projects, companies must prioritize creativity and innovation in their design approach.

To get online demonstration, watch the following video tutorial.

Video Source: Vision Miner

The potential of 3D printing technology can help interior design firms remain competitive and thrive in this market. In terms of design, 3D printing offers many advantages that will enhance customization and provide clients with unique and cutting edge designs.

Interior design firms can showcase their adaptability to modern technology by integrating 3D printing to their designing for getting great design outcomes & get amongst as industry leaders. Adopting 3D printing can be game changer to stand out to your competitor & gain sustainable growth.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !