Revolutionizing Automotive Design: The Role of BIM and Its Future

Tweet

Innovation in the automotive industry is not limited to the vehicles themselves. The process of designing and manufacturing cars and other automobiles has seen a transformative shift, thanks to Building Information Modeling (BIM).

Typically associated with architecture and construction, BIM is now playing a pivotal role in the automotive sector, revolutionizing the way vehicles are designed, tested, and brought to market.

Understanding BIM in the Context of Automotive Design

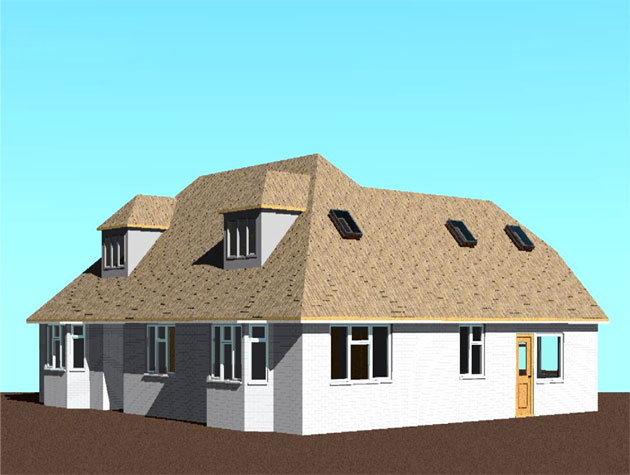

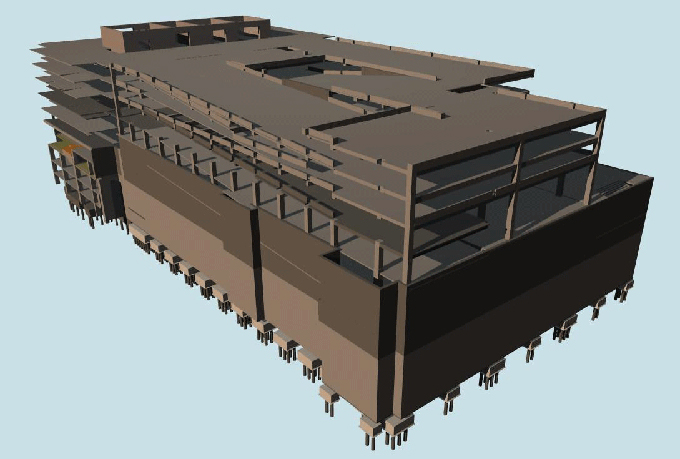

Digital representations of the physical and functional characteristics of buildings are called building information modelling (BIM). It is a process that spans the entire lifecycle of an asset, from concept to construction to operation.

While originally developed for architecture and construction, the principles of BIM can be seamlessly adapted for designing and manufacturing automobiles.

The Core Principles of BIM

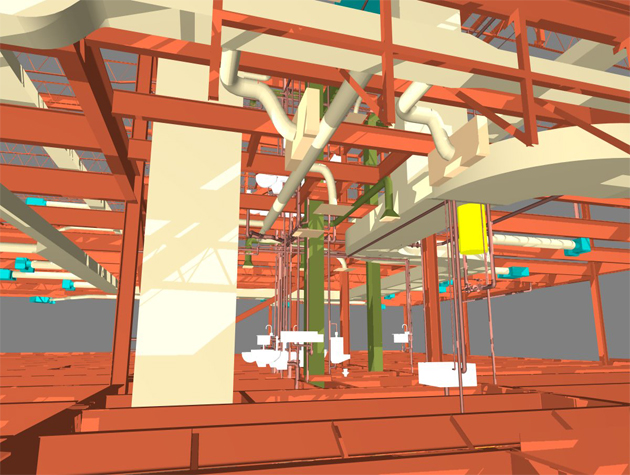

1. Digital Representation: BIM creates a comprehensive digital model of the vehicle, incorporating every detail, from mechanical components to electrical systems.

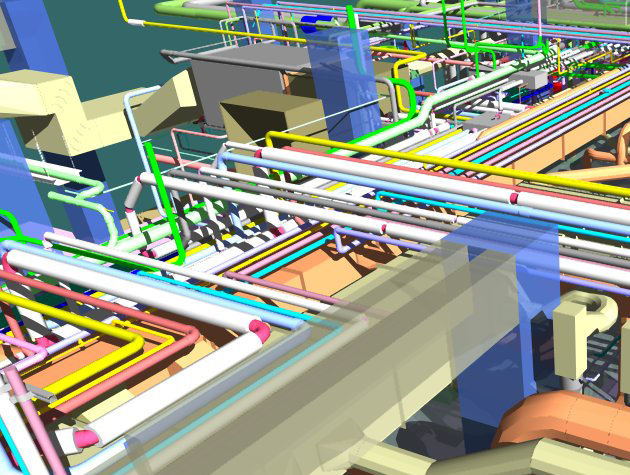

2. Collaboration: BIM promotes collaborative work among various teams involved in the design process, ensuring that everyone works with the most up-to-date information.

3. Data-Driven Decisions: BIM relies on accurate data, allowing designers and engineers to make informed decisions based on real-world information.

4. Iterative Design: BIM facilitates iterative design, allowing for easy modifications and updates as the design process progresses.

Advantages of Using BIM in Automotive Design

The integration of BIM in automotive design offers several compelling advantages:

1. Enhanced Collaboration

BIM promotes collaboration among cross-functional teams, including designers, engineers, and manufacturers. It ensures that everyone involved has access to the same data, reducing communication barriers and the likelihood of errors.

2. Streamlined Design Process

The use of BIM allows for a streamlined design process. Changes and modifications can be made quickly, and the effects of these changes can be analyzed in real-time, resulting in more efficient and effective design iterations.

3. Accurate Prototyping

BIM enables the creation of highly accurate digital prototypes, reducing the need for physical prototypes. This not only saves time but also significantly reduces costs associated with physical testing.

4. Data-Driven Decision Making

With BIM, decisions are data-driven. Designers and engineers can analyze various scenarios and make informed choices based on the data provided by the model.

5. Cost and Time Savings

By eliminating errors and inefficiencies in the design process, BIM ultimately leads to cost savings. It reduces the need for rework and enables projects to stay on schedule.

Applications of BIM in Automotive Design

The applications of BIM in the automotive industry are diverse and impactful, spanning the entire lifecycle of vehicle development:

1. Conceptual Design

BIM facilitates the creation of digital prototypes during the conceptual design phase. Designers can explore various concepts and iterate quickly, narrowing down design choices efficiently.

2. Detailed Design

During the detailed design phase, BIM helps engineers and designers create intricate 3D models that include every component, from the engine to the interior features.

3. Simulation and Testing

BIM models are used for virtual testing and simulation. This includes analyzing the vehicle's performance under different conditions, such as crash testing and aerodynamics simulations.

4. Manufacturing

BIM data is invaluable in the manufacturing process. It can be used to generate accurate toolpaths for CNC machines, enabling precise manufacturing of parts and components.

5. Maintenance and Repairs

After a vehicle is on the road, BIM data continues to be valuable for maintenance and repairs. Accurate digital models can help in diagnosing issues and planning maintenance schedules.

6. Sustainability

BIM can be used to analyze the environmental impact of vehicles, helping manufacturers design more sustainable and eco-friendly automobiles.

The Future of BIM in Automotive Design

The adoption of BIM in automotive design is still in its early stages, but its future holds tremendous promise:

1. Autonomous Vehicle Development

As autonomous vehicles become more prevalent, BIM will play a crucial role in their design and testing. Accurate digital models will be essential for simulating and validating the performance of self-driving systems.

2. Electric Vehicle Revolution

The shift towards electric vehicles (EVs) is accelerating, and BIM can assist in optimizing the design of EV components and battery placement for improved efficiency and range.

3. Customization and Personalization

Consumers increasingly seek customization and personalization options in their vehicles. BIM can enable manufacturers to efficiently accommodate these demands, allowing for tailored vehicle configurations.

4. Sustainable Design

BIM's ability to analyze environmental impact aligns perfectly with the automotive industry's growing emphasis on sustainability. Manufacturers will use BIM to create more eco-friendly vehicles and reduce their carbon footprint.

5. Supply Chain Integration

BIM can facilitate tighter integration with supply chains. Manufacturers can use BIM data to streamline the production process and optimize the flow of parts and components.

6. Enhanced Safety

With the help of BIM, manufacturers can design safer vehicles by simulating and testing various safety scenarios, from crashworthiness to pedestrian protection.

7. Rapid Prototyping

The use of BIM in 3D printing and rapid prototyping technologies will continue to grow, enabling quicker development cycles and faster time-to-market for new vehicle models.

To get online demonstration, watch the following video tutorial.

Video Source: SimScale

Challenges and Considerations

While the future of BIM in automotive design looks promising, there are challenges and considerations to keep in mind:

1. Data Security: Protecting sensitive design data within the BIM model is essential to prevent intellectual property theft.

2. Integration: Ensuring seamless integration of BIM tools with existing design and manufacturing software can be complex.

3. Skillset: Manufacturers will need to invest in training their workforce to effectively use BIM tools and processes.

4. Standardization: Widespread adoption may require industry-wide standardization to ensure compatibility and interoperability.

Conclusion

Building Information Modeling (BIM) is reshaping the automotive industry, bringing a new level of precision, efficiency, and sustainability to the design and manufacturing process of cars and other automobiles. Its impact is already evident, with applications ranging from conceptual design to manufacturing, testing, and beyond.

As technology continues to advance, BIM will play an increasingly central role in the development of autonomous vehicles, electric cars, and highly customized vehicles. The automotive industry is on the brink of a digital transformation, where BIM will be at the forefront of innovation, driving the creation of safer, more efficient, and environmentally friendly automobiles.

With careful consideration of challenges and a commitment to skill development, the future of BIM in automotive design promises to be both exciting and transformative, ultimately benefiting consumers and the industry as a whole.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !