Revolutionizing Footwear Design and Production: The Role of Building Information Modeling (BIM)

Tweet

In a world where technology continues to transform industries, it's not surprising to see innovative tools and methodologies applied in unexpected places. Building Information Modeling (BIM), a technology originally designed for the construction and architecture sectors has found a unique and exciting application in the world of footwear design and production.

What is BIM?

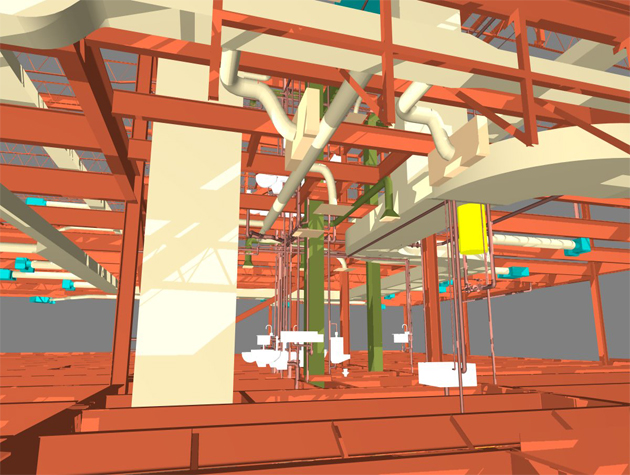

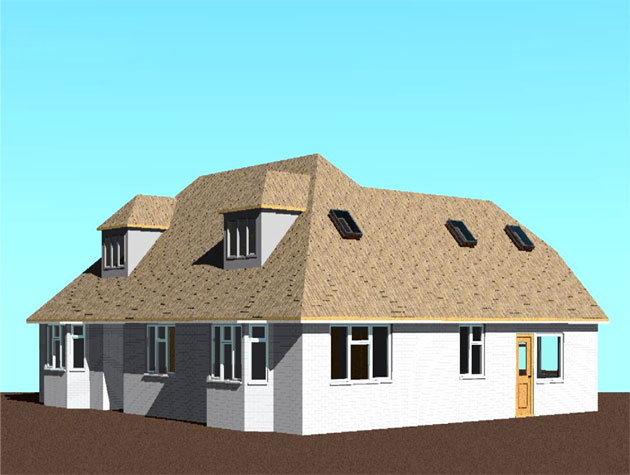

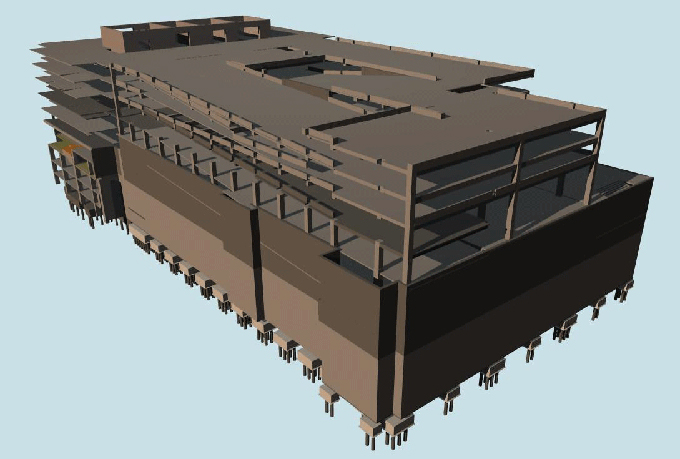

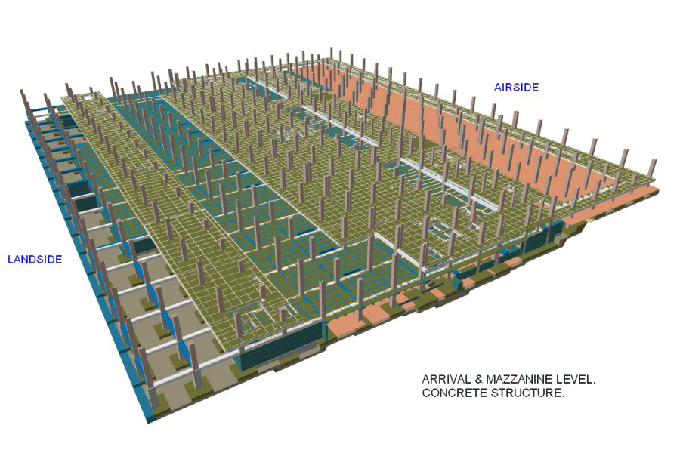

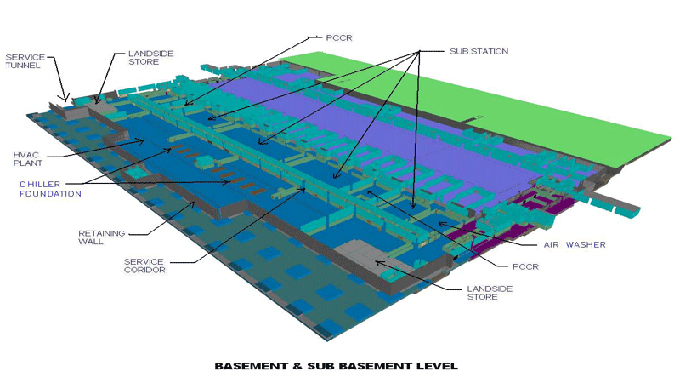

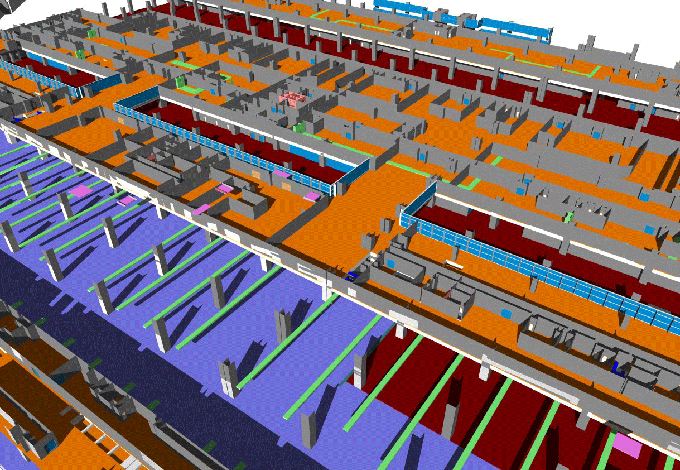

Before delving into its application in the footwear industry, it's important to understand what BIM is and how it works. Building Information Modeling is a digital process that involves creating a comprehensive 3D model of a building or structure, which includes all relevant data and information about the project.

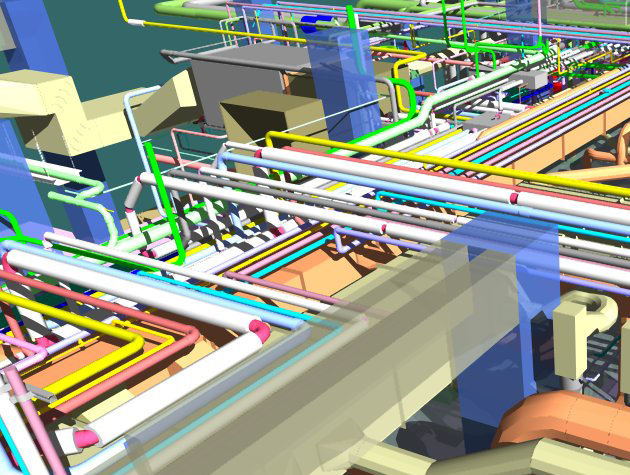

BIM goes beyond traditional 3D modelling by incorporating data on materials, construction phases, costs, and performance characteristics, among other elements. It allows various stakeholders in the construction industry to collaborate, visualize, and simulate a project before it is built, ultimately leading to more efficient and cost-effective construction.

BIM in the Footwear Industry

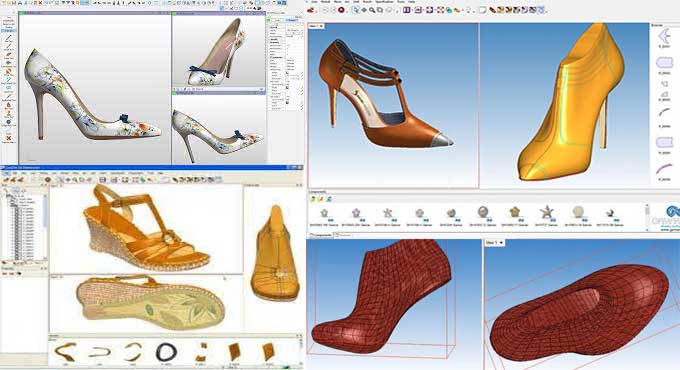

The footwear industry, like many others, has embraced technological advancements to enhance efficiency, reduce waste, and improve product quality. The application of BIM in footwear design and production is a relatively new but rapidly growing trend. Here's how BIM is making its mark in the world of footwear:

1. Digital Prototyping and Visualization

BIM allows footwear designers to create digital prototypes of shoes, providing a highly detailed and accurate representation of the final product. This enables designers to visualize their ideas and concepts in a 3D space, making it easier to experiment with various designs and materials.

2. Collaboration and Communication

Just as in construction projects, BIM facilitates collaboration in the footwear industry. Designers, engineers, and manufacturers can work together on a single digital platform, making it easier to share ideas and data, thus improving the overall quality and speed of the design process.

3. Material Selection and Simulation

One of the most significant advantages of BIM in footwear design is the ability to simulate the behaviour of different materials. This helps in selecting the right materials for specific purposes, such as improving cushioning, flexibility, or durability. Designers can see how various materials will perform before actually creating physical prototypes.

4. Customization and Mass Production

BIM also plays a crucial role in customizing footwear. With the 3D model of a shoe, it becomes possible to tailor designs to individual customers' preferences and needs. Once a custom design is finalized, BIM can be used to guide automated manufacturing processes, enabling efficient mass production of custom footwear.

5. Sustainability and Waste Reduction

By allowing for precise material simulation and digital prototyping, BIM helps reduce waste in the manufacturing process. Less material is wasted on physical prototypes, and efficient material usage contributes to sustainability efforts in the footwear industry.

6. Quality Control and Testing

Footwear manufacturers can use BIM to simulate the wear and tear of a shoe, helping to identify potential issues with the design. It also allows for virtual testing and quality control, ensuring the final product meets performance and safety standards.

Advantages of Using BIM in Footwear Design and Production

The use of BIM in footwear design and production offers a multitude of advantages that are reshaping the industry:

A. Efficiency: BIM streamlines the design and manufacturing processes, reducing lead times and production costs. It enables designers to make real-time adjustments and decisions, leading to faster time-to-market.

B. Customization: Custom-made footwear is in high demand, and BIM facilitates the design of personalized shoes, meeting the unique needs and preferences of customers.

C. Cost Reduction: Through simulation and prototyping, BIM minimizes the need for physical samples and prototypes, saving time and money.

D. Sustainability: BIM helps optimize material usage, reducing waste and contributing to a more sustainable and environmentally friendly manufacturing process.

E. Quality Assurance: The ability to simulate wear and tear and conduct virtual tests ensures that footwear meets quality and safety standards.

F. Streamlined Supply Chain: Improved communication and collaboration across the supply chain result in smoother, more efficient production.

Disadvantages and Challenges

While BIM offers significant advantages in the footwear industry, it is not without its challenges:

A. Adoption Costs: Implementing BIM systems and training staff can be costly, particularly for smaller footwear manufacturers.

B. Data Security: Storing and sharing sensitive design and manufacturing data digitally raises concerns about data security and intellectual property protection.

C. Technical Expertise: Effective use of BIM requires specialized knowledge and expertise, which may necessitate hiring or training skilled personnel.

D. Resistance to Change: Like any industry, the footwear sector may encounter resistance to adopting new technologies and processes.

Case Studies: BIM in Footwear

Several prominent footwear brands and manufacturers have already recognized the benefits of BIM in their design and production processes:

A. Adidas: Adidas uses BIM to optimize the design of athletic shoes, improving performance characteristics and reducing production time. The company also uses 3D printing to create customized midsoles.

B. Nike: Nike employs BIM to streamline the design and manufacturing of its shoes, leading to more efficient production and reducing waste. The company's Flyknit technology is an example of BIM-driven innovation.

C. New Balance: New Balance incorporates BIM to create custom-made shoes that cater to each customer's unique foot shape and gait. This approach has been highly successful in providing personalized athletic footwear.

The Future of BIM in Footwear

As technology continues to evolve, it is expected that the use of BIM in the footwear industry will become increasingly common. The advantages of BIM, including cost reduction, customization, and sustainability, align with the demands of the modern consumer. Furthermore, as 3D printing technology becomes more accessible and sophisticated, the integration of BIM with 3D printing is likely to play a pivotal role in the future of footwear design and production.

To get online demonstration, watch the following video tutorial.

Video Source: Brendan Hasty

Conclusion

The application of BIM in the footwear industry represents a significant shift in how shoes are designed and manufactured.

It offers an array of benefits, including efficiency, customization, cost reduction, and sustainability. As the technology continues to advance and footwear companies recognize its potential, we can expect to see a transformation in the way we conceive, design, and produce footwear. The digital era has undoubtedly left its mark on the world of shoes, and BIM is poised to reshape the industry for years to come.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !