The 10 best Warehouse Floor Plan Design Tactics for your company

Tweet

You can make or break your business productivity based on the 3D floor plan design of your warehouse. It can ultimately lead to lost labor hours, increased picking times, and increased safety risks. Here are some strategies you can use to improve your warehouse, whether you are building it from scratch or tweaking your current one.

Set Your Objectives

For efficient warehouse design and 3D warehousing, defining the objectives is crucial. Your organizational warehousing strategy must be in alignment with these objectives. At a high level, you can set goals like providing maximum customer service and reducing warehouse expenses.

Additionally, objectives can be specific, including improving warehouse efficiency through CAD modeling without boosting resources, providing maximum warehouse flexibility, and maximizing warehouse space.

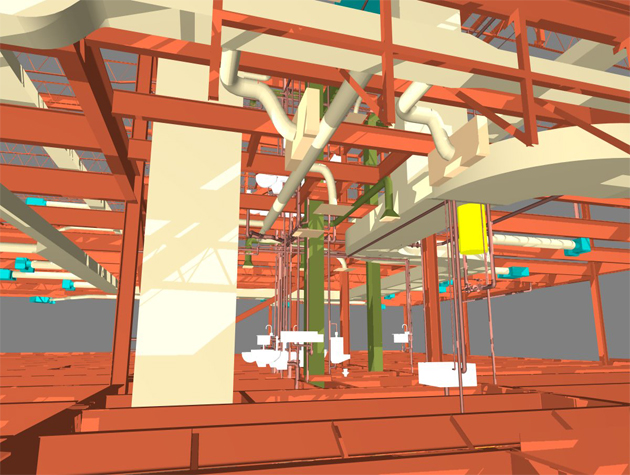

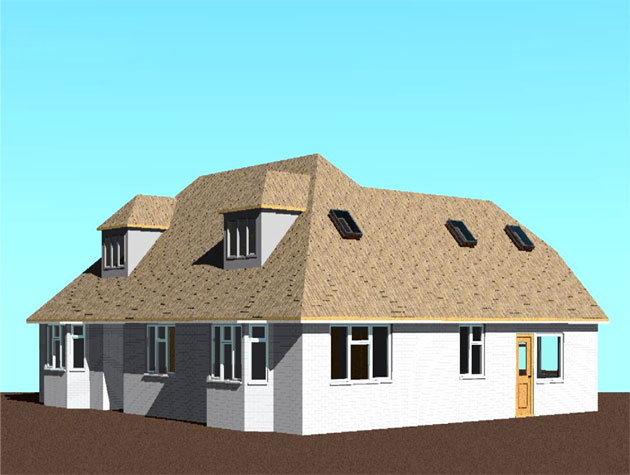

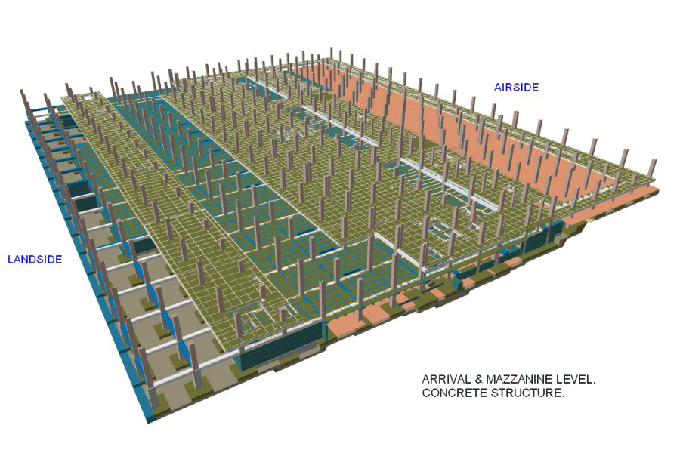

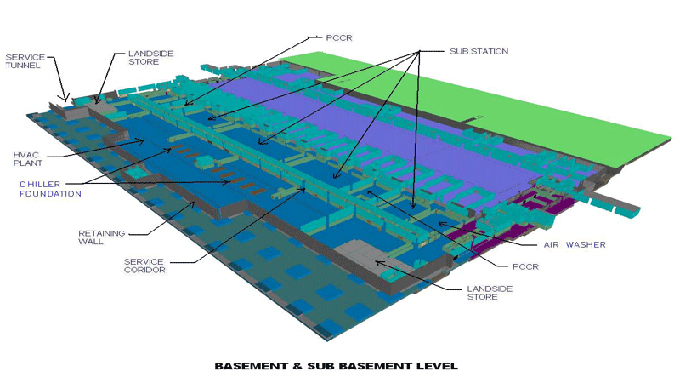

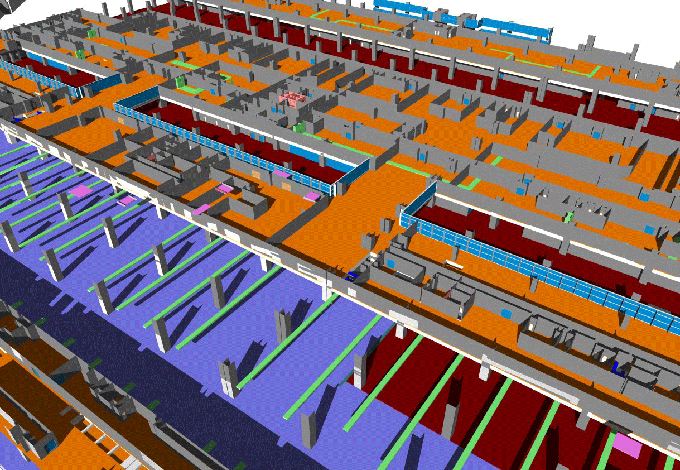

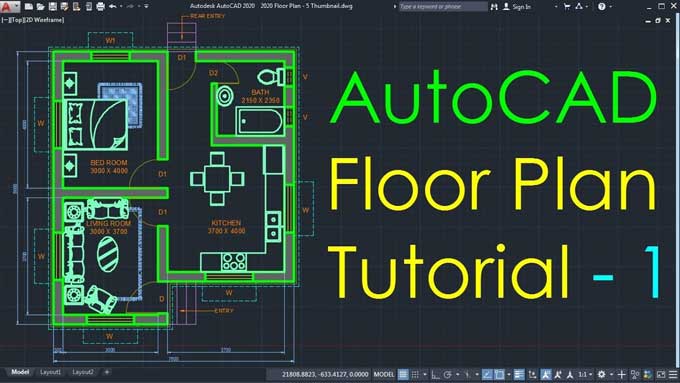

Floor plans and 2D drawings are typically the first steps in the design and rendering process of 3D floor plans. To create 3D warehouse CAD designs, companies can use 3D floor plan design services.

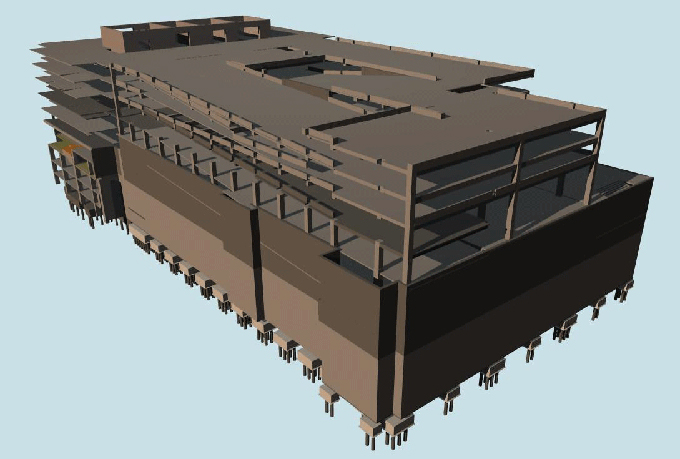

Warehouse CAD Design for Now & Near Future

Design your warehouse's 3D floor plan based on future needs, not just today's needs. You should also create 3D floor plans that will allow the project to grow in the future. Empty warehouses and overcrowded existing spaces are common issues when designing a 3D warehouse floor plan. Putting your ideas and concepts on paper is a good idea. AutoCAD 3D designers may look great when designing your warehouse floor plan, but it's still important to start with paper and pencil, as a starting point.

Your company's rapid growth will depend on how well the 3D floor plan is designed. The most critical task is creating an efficient material flow before reaching the final destination. If you have adequate space, the right equipment & storage mediums, you can instantly achieve an efficient flow of materials. Predicting future growth and designing floor plans for the present and the future will be beneficial.

Getting Information from Contractors and Managers

You may be tempted to start designing your 3D warehouse floor plan right away. The design of a 3D warehouse can be a severe mistake without the input of others. Talk to your warehouse managers, your material handling company, and even your company's drivers about what you need. Businesses that need assistance with 3D floor plans can hire freelancers.

Their experience in warehousing, planning, facility operations and expertise within your warehouse makes them an effective resource for 3D warehousing and CAD design. The floor plan design should be based on your requirements and goals as well as your recommendations.

Floor Plan Design Testing before Installation

You can ensure that everything in your warehouse is ready for installation before installing shelves, pallet racks, or equipment. Masking tape can be used to outline major work areas. By carrying things through it or rolling around pallet jacks, you can simulate work simultaneously with other employees. As a result, you will have a better understanding of the space and be able to determine whether or not it is optimized. Despite minor errors here, they may lead to more serious mistakes in the future.

Schematic Design

Writing everything down on paper first is always the key to designing an effective warehouse floor plan, no matter how big or small the space is. The blueprint for the warehouse can be used for this purpose. It is particularly important if the space is large or does not fit into a standard rectangle shape. Upon renting, your landlord can provide you with a copy of the existing floor plan.

A 3D warehouse design schematic can be drawn on grid paper if you do not have a blueprint copy. If you have a schematic, you might want to consider using one square per square foot. The existing floor plan design can also be created by freelancers who specialize in 2D drawings and floor plans.

Familiarize with Local Building Codes

If you are designing a 3D warehouse, please make sure you know the local building codes regarding warehouse product storage. You must take into consideration other safety considerations, such as pedestrian traffic versus forklift aisles, egress paths, etc.

Your warehouse floor plan will be significantly improved if you incorporate this information. You can also have your warehouse designed using 2D CAD drafting services.

Get Used to Warehouse Inventory

The inventory you will store there is as important as understanding your specific work processes. The size and shape of these items will need to be determined, as well as the materials handling equipment necessary to transport them. The importance of this in-depth understanding can be attributed to several factors. A few essentials are the item's size, so whether the item is the same or not, you won't have as much space for other items in your inventory.

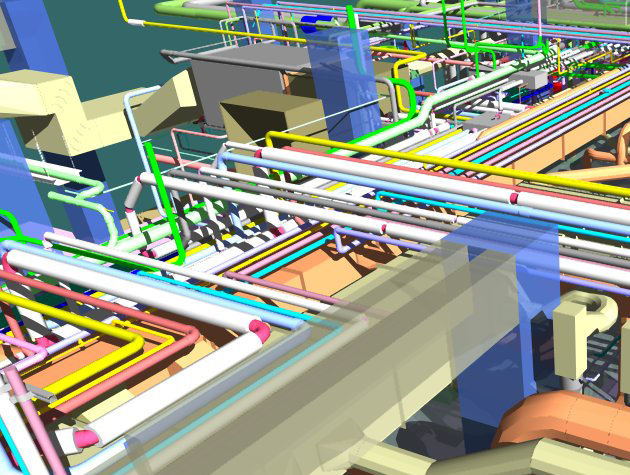

Logistics Movement

The term circulation refers to the movement of goods in logistics, such as receiving, preparing orders, and dispatching. High-rotation products have higher outputs and inputs because they are replaced more frequently. If the company's operational procedures admit it, it is better to lessen the movement of loads. In order to design an effective 3D warehouse and a 3D floor plan, it is essential to identify these flows.

Warehouse Management System (WMS)

Using your warehouse management system, you can access historical data. Today's cut throat business environment requires data collection, so consider investing in a WMS. A WMS can assist in designing your facility's 3D warehouse and CAD design floor plans.

In modern WMS, inventory is not only tracked but also operational data is collected. An inventory management system can suggest alternatives to traditional product categorization, such as floating inventory floor plans, to increase product slotting efficiency.

To get online demonstration, watch the following video tutorial.

Video Source: The Minimalist Society

Spatial Relationships between different Warehouse Parts

The details of how these parts are connected must be considered in several ways. It may be detrimental to warehouse design flow to underestimate or overestimate any single factor.

Identifying how much space is needed in each area is the next step of the phase. Several methods can be used to accomplish this task, and some may be more appropriate than others depending on the situation. In some facilities, space standards have already been established, while in others, historical information is required to lay out the parts.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !