The Future of CAE Simulations and its Applications in 2023

Tweet

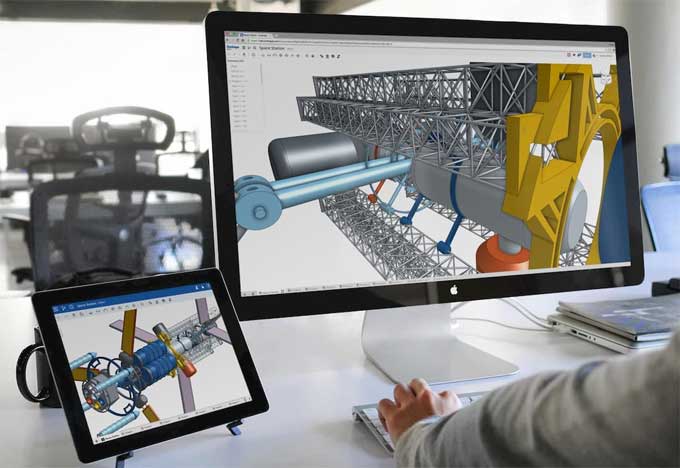

Based on computer aided engineering, engineering projects are prototyped on a screen and engineered. Physical tests are used to simulate a product's performance under different conditions. So long as the engineering data and environmental variables are accurate, simulated results should be identical to those generated by physical testing.

CAE Simulations

One of the most important benefits of computer aided engineering (CAE) is its ability to simulate product functionality and use in a virtual environment. By simulating various real world scenarios on a computer, engineers can see and predict how a given product will behave, react, and perform in diverse environments and situations.

Real Time Crash Test in CAE Simulations

In order to determine whether an accident will cause harm, auto manufacturers no longer conduct crash tests on actual cars. A virtual crash test with CAE software can be used to identify design flaws in a vehicle and then strengthen them to make it safer.

The crash test required two to three sacrificial vehicles. By anticipating and averting unsuccessful testing, the simulation program can lower design expenses. Before completing the design, the engineers can make improvements based on the results of simulations. In the end, the factory just needs to deliver one vehicle to the test, and it will be a complete success.

Cost Efficiency

Engineers frequently reduce the amount of materials used in a design to maximize cost efficiency. Simulation results can show the extent of the subtraction needed to maintain structural strength and performance while maintaining a minimal cost. The same holds true for product durability, fuel efficiency, and ergonomics. It is challenging to overstate the importance of CAE in contemporary design and manufacturing industries.

Physical Prototype

Prior to the usage of CAE simulations, robust product research and development relied on actual field tests with a physical prototype. Although CAE has not completely replaced physical testing, it has significantly increased the effectiveness of such testing. The program enables the construction of a digital environment for testing as well as a virtual prototype without the need for potentially costly mock-ups.

Even if CAE provides a more useful solution, many startups and new business owners continue to use physical prototypes. Cost is the main barrier preventing the widespread implementation of CAE. While some commercial CAE software programs require a subscription, others can be bought once.

The monthly fee ranges from $30 to $100 or more, and premium CAE can cost hundreds of dollars per user. The challenging learning curve is still another issue. Even while there are useful resources online, it still takes the average person months or even years to acquire everything they need to know.

CAE Software Applications

Multiple prototype iterations are necessary during the product development process. Every design modification necessitates a fresh mock-up because any iteration signifies a significant advancement. Cost efficiency depends on building any iteration correctly the first time.

A single prototype may cost hundreds or even thousands of dollars to produce if the device has distinctive pieces or custom components that require specialized tooling. Performance and endurance testing might potentially irreparably harm the physical prototype, necessitating the creation of a new one by engineers.

Every business that develops and markets products for mass production should employ CAE to increase operational effectiveness. Lower manufacturing costs, a shorter design cycle, and a speedier time to market can all contribute to the improvement.

Automotive Companies

The CAE program provides more than enough tools to model vehicle performance in the real world, regardless of whether the company manufactures cars, motorcycles, trains, or aircraft.

To get online demonstration, watch the following video tutorial.

Video Source: Ekeeda

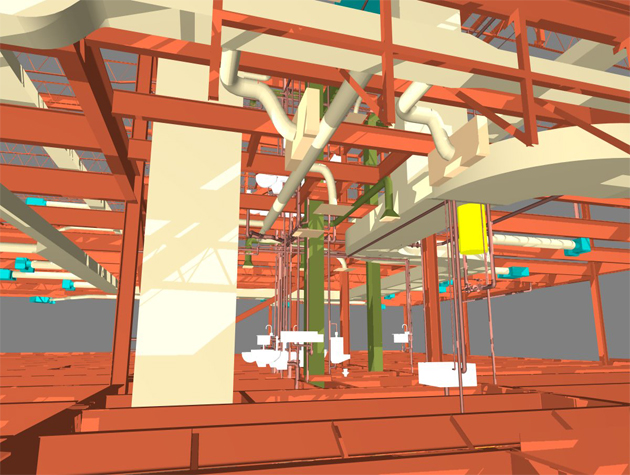

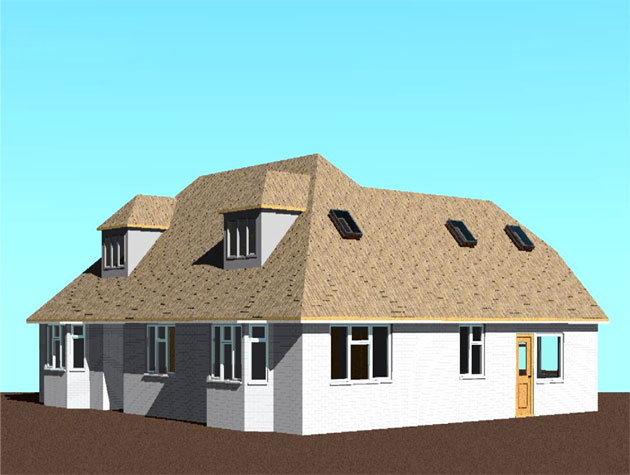

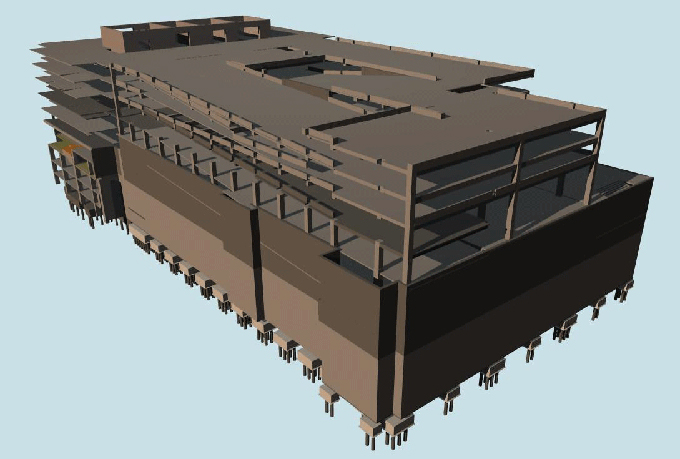

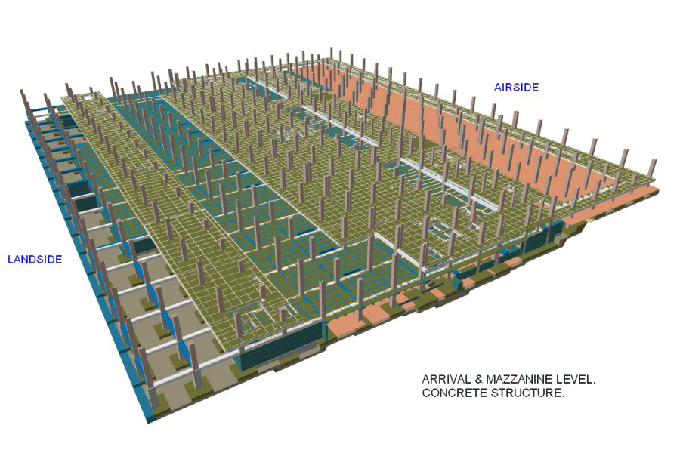

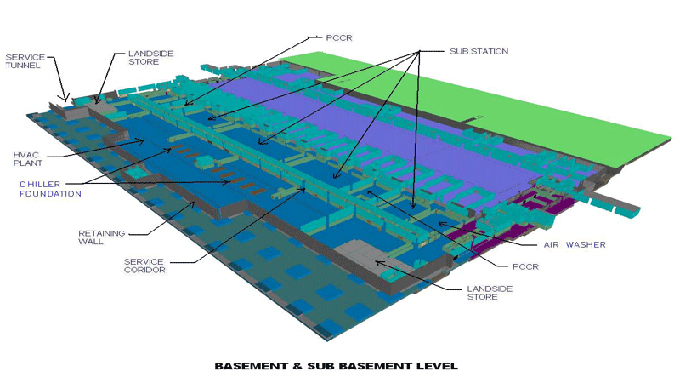

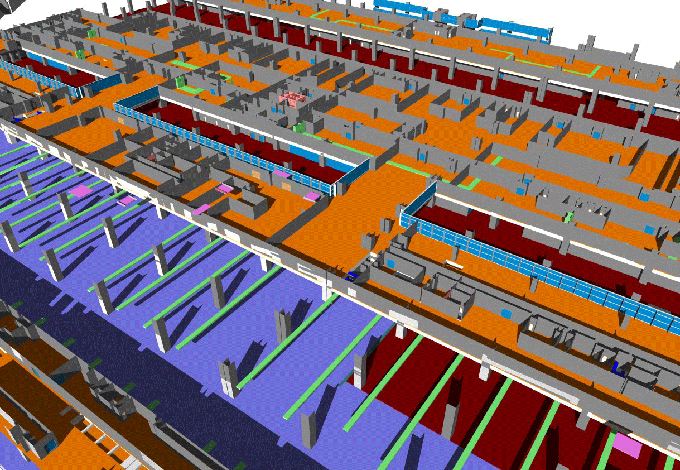

Structural Engineering Companies

Before building starts, architectural companies can test out several design choices using simulation services or software. Contrary to CAD, which prioritizes the modeling aspect of a project, CAE provides precise virtual modeling in addition to engineering calculations. Additionally, the businesses offer screen based effect and stress studies.

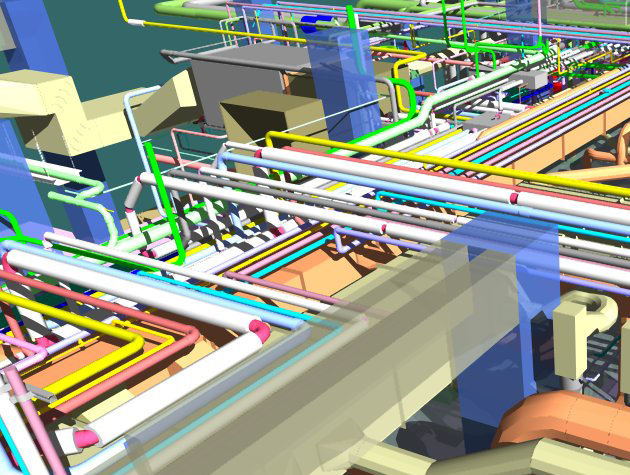

Industrial Equipment Companies

It takes a lot of resources to physically test massive, heavy duty industrial machinery. From the initial stages of development to conclusion, CAE aids in engineering design optimization. It is substantially less expensive to develop when strength, reliability, safety, and durability are virtually tested.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !