Analyzer CAD: A Seamless Bridge between Design and Production

Tweet

For woodworkers and furniture makers, the journey from design concept to finished product can be long and arduous. It often involves multiple software programs, manual calculations, and time-consuming data transfers. Analyzer CAD, a revolutionary plug-in for AutoCAD, aims to streamline this process by offering a seamless bridge between design and CNC-ready production.

Understanding Analyzer CAD

Analyzer CAD is an advanced plug-in designed exclusively for woodworking experts that use AutoCAD as their primary design programme. It acts as a complete interface, easing the transfer from sophisticated AutoCAD drawings to CNC-ready production using Analyzer Manufacturing. This plug-in is designed to solve the special issues and requirements of the woodworking industry, with a variety of features that improve design accuracy, expedite processes, and optimize the whole production process.

Key Features of Analyzer CAD

Seamless Integration with AutoCAD:

Analyzer CAD seamlessly integrates with AutoCAD, creating a cohesive environment for woodworkers to design and model their projects with precision. This integration ensures that the transition from the design phase to the manufacturing phase is smooth and efficient, reducing the likelihood of errors and streamlining the overall production workflow.

Custom Woodworking Libraries:

Recognizing the diversity of woodworking projects, Analyzer CAD comes equipped with custom woodworking libraries. These libraries house an extensive collection of parametric components, materials, and textures tailored specifically for woodworking applications. This feature not only accelerates the design process but also ensures that the final product aligns with industry standards and client specifications.

Parametric Design Capabilities:

One of the standout features of Analyzer CAD is its robust parametric design capabilities. Woodworkers can create parametric designs that are easily adjustable, allowing for rapid iterations and modifications without compromising accuracy. This flexibility is particularly valuable when dealing with intricate or custom designs that may require frequent adjustments.

Precise 3D Modeling:

Analyzer CAD enhances the 3D modeling capabilities within AutoCAD, enabling woodworkers to create highly detailed and accurate representations of their designs. The precision offered by Analyzer CAD in 3D modeling is crucial for visualizing the final product and identifying potential issues before moving to the manufacturing stage.

Automatic Toolpath Generation:

Streamlining the transition from design to production, Analyzer CAD automates the toolpath generation process for CNC machining. This automation reduces the likelihood of errors and ensures that the CNC machine receives accurate instructions, translating the design into a physical product with unparalleled precision.

Material Optimization and Cost Estimation:

Analyzer CAD goes beyond design and toolpath generation by incorporating material optimization and cost estimation features. Woodworkers can analyze the material requirements of their designs, minimizing waste and maximizing efficiency. Additionally, the plugin provides accurate cost estimates, aiding in project budgeting and financial planning.

Compatibility with Analyzer Manufacturing:

The seamless bridge between Analyzer CAD and Analyzer Manufacturing is a key strength of this plugin. By preserving design integrity and translating it effortlessly into CNC-ready instructions, Analyzer CAD ensures a consistent and reliable connection between the digital design and the physical production process.

Benefits of using Analyzer CAD

• Increased efficiency: Streamline your workflow by eliminating the need for multiple software programs and manual data entry.

• Reduced errors: Minimize the risk of errors with automated part recognition, toolpath generation, and material selection.

• Improved accuracy: Get consistent and accurate results with built-in libraries and calculations.

• Enhanced productivity: Spend less time on tedious tasks and more time on design and production.

• Cost savings: Minimize material waste and optimize production processes for better cost control.

• Simplified production: Seamlessly integrate design data with Analyzer Manufacturing for efficient CNC production.

Benefits of Analyzer CAD for Woodworkers

Time Efficiency:

The integration of Analyzer CAD with AutoCAD and Analyzer Manufacturing significantly reduces the time required for the entire design-to-production cycle. Woodworkers can efficiently move from conceptualizing intricate designs to producing CNC-ready instructions, streamlining their workflow and increasing overall productivity.

Enhanced Precision:

Precision is paramount in woodworking, and Analyzer CAD delivers on this front. The plugin's parametric design capabilities and 3D modeling features contribute to the creation of highly accurate representations of designs. This precision not only ensures the quality of the final product but also minimizes the risk of errors during CNC machining.

Increased Design Flexibility:

Woodworkers often encounter the need for design modifications based on client feedback or project requirements. Analyzer CAD's parametric design capabilities empower users with increased design flexibility, allowing for quick and efficient modifications without compromising accuracy.

Cost Savings through Material Optimization:

The material optimization feature in Analyzer CAD helps woodworkers make informed decisions about material usage, reducing waste and optimizing cost. This not only contributes to environmental sustainability but also enhances the economic viability of woodworking projects.

Accurate Cost Estimation:

Analyzer CAD's ability to provide accurate cost estimates aids woodworkers in project budgeting and cost management. This feature ensures that projects are financially viable and that woodworkers can deliver high-quality products within budget constraints.

Seamless Collaboration:

The compatibility between Analyzer CAD and Analyzer Manufacturing facilitates seamless collaboration between designers and manufacturers. This streamlined communication ensures that the final product faithfully reflects the designer's intent, fostering a collaborative and efficient production environment.

Case Studies: Real-world Applications of Analyzer CAD

Custom Furniture Design:

In a custom furniture design scenario, Analyzer CAD proved instrumental in translating intricate designs into CNC-ready instructions. The parametric design capabilities allowed for quick adjustments to accommodate client preferences, while the automatic toolpath generation ensured that the CNC machine executed the design with unparalleled precision. The result was a bespoke piece of furniture that met both aesthetic and functional requirements.

Architectural Woodwork:

For architectural woodwork projects, where precision and consistency are paramount, Analyzer CAD demonstrated its ability to streamline the design and manufacturing process. The custom woodworking libraries and material optimization features ensured that the finished products met industry standards while minimizing material waste. This not only enhanced the quality of the architectural elements but also contributed to overall project cost savings.

Cabinetmaking:

Cabinetmaking requires meticulous attention to detail, and Analyzer CAD excelled in this domain. Woodworkers were able to create highly detailed 3D models of cabinets, incorporating parametric design elements to accommodate specific spatial constraints. The automatic toolpath generation feature then translated these designs into CNC-ready instructions, resulting in cabinets that met exact specifications.

Challenges and Considerations

While Analyzer CAD offers a myriad of benefits for woodworking professionals, it's essential to acknowledge potential challenges and considerations:

Learning Curve:

Embracing new software tools often comes with a learning curve. Woodworkers transitioning to Analyzer CAD may require training to fully leverage its capabilities. However, the investment in training can yield significant long-term benefits in terms of increased efficiency and precision.

To get online demonstration, watch the following video tutorial.

Video Source: Techie BUD

Software Integration:

Ensuring seamless integration between Analyzer CAD, AutoCAD, and Analyzer Manufacturing requires attention to software compatibility and updates. Regular updates and support from the software providers are crucial to maintaining a smooth workflow and addressing any compatibility issues that may arise.

Hardware Requirements:

The efficient functioning of Analyzer CAD may be influenced by the hardware specifications of the user's system. Woodworkers should consider whether their existing hardware meets the recommended requirements to fully capitalize on the capabilities of the plug-in.

Analyzer CAD: The future of woodworking

Analyzer CAD is rapidly becoming a game-changer for woodworkers and furniture makers of all sizes. Its intuitive interface, powerful features, and seamless integration with Analyzer Manufacturing provide a comprehensive solution for digital woodworking. By bridging the gap between design and production, Analyzer CAD empowers woodworkers to create high-quality products with greater efficiency and profitability.

Conclusion

Whether you are a seasoned woodworker or just starting out, Analyzer CAD can revolutionize your workflow. With its intuitive design, powerful features, and seamless integration with Analyzer Manufacturing, it offers a complete solution for taking your designs from concept to finished product seamlessly and efficiently. So, if you're looking to streamline your woodworking process, enhance your productivity, and improve your bottom line, Analyzer CAD is the perfect tool for you.

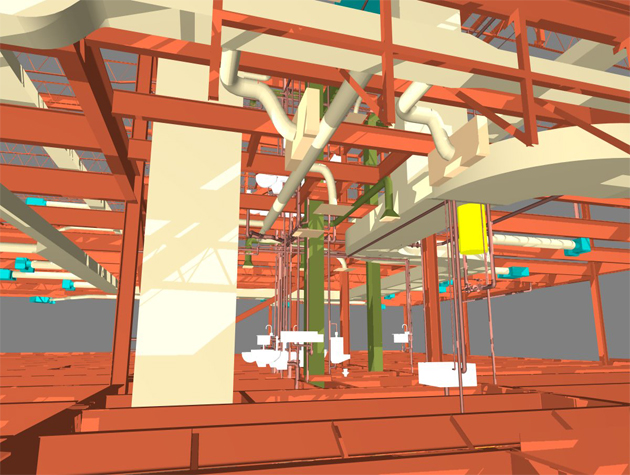

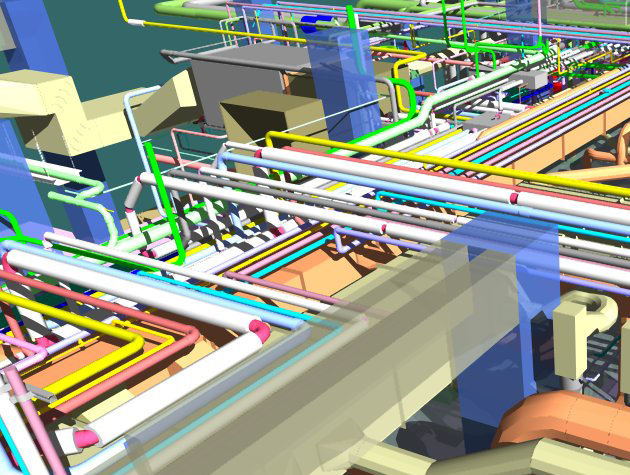

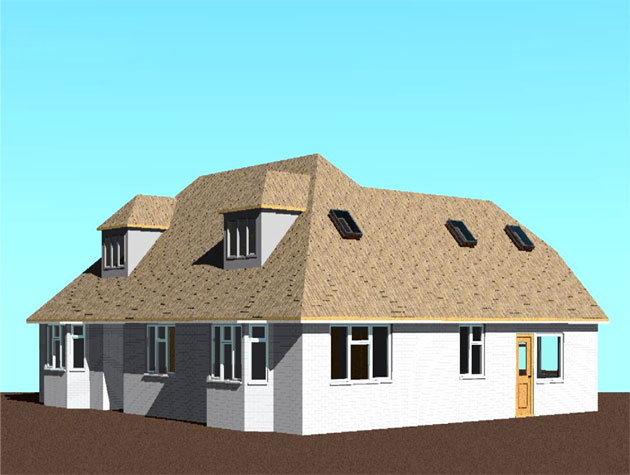

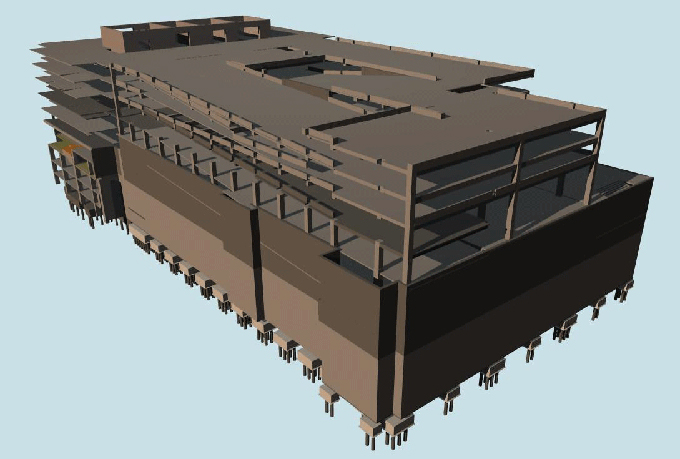

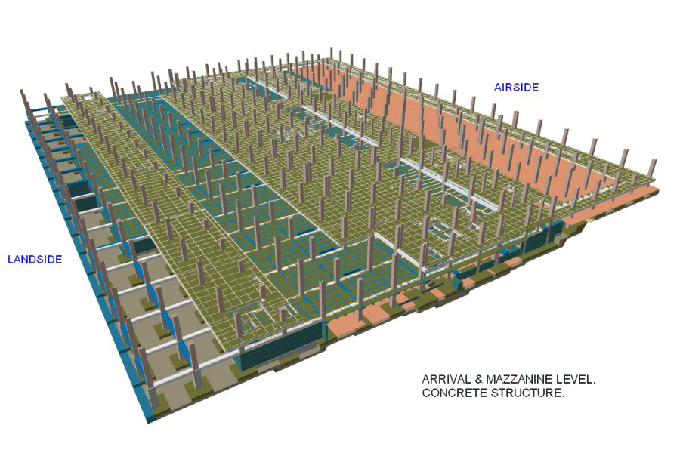

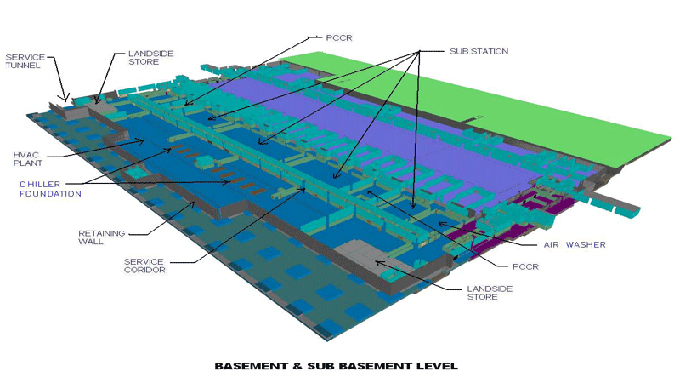

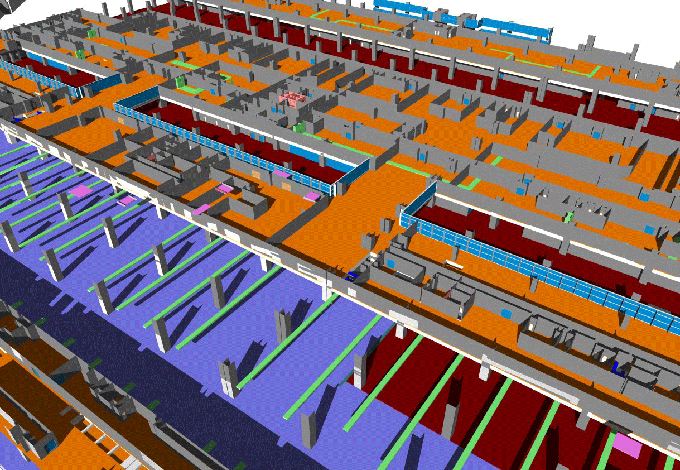

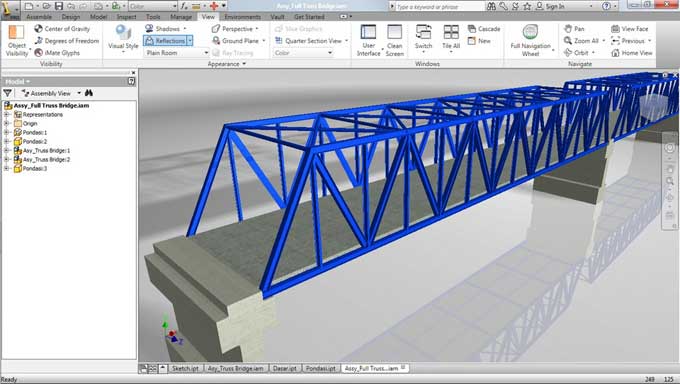

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !