Electrifying Innovation: How BIM is paving the Road for the Future of Electric Vehicles

Tweet

The race for a sustainable future is accelerating, and the automotive industry is at the forefront, with electric vehicles (EVs) leading the charge. But beyond flashy design and sleek features, the key to truly electrifying the future lies in efficient and sustainable development and manufacturing processes. This is where Building Information Modeling (BIM) emerges as a game-changer, empowering the EV revolution with unprecedented precision and collaboration.

BIM: The Blueprint for a Better EV Future

BIM is more than just 3D modeling software; it is a collaborative platform that integrates all aspects of a project, from design and engineering to construction and operation, into a single, centralized digital model. This data-rich environment offers a multitude of benefits for the development and manufacturing of EVs:

1. Streamlined Design and Engineering:

• Virtual Prototyping: BIM allows for rapid iteration and testing of EV designs in a virtual environment, identifying and addressing potential issues early on. This eliminates costly physical prototypes and saves time, resources, and ultimately, money.

• Integrated Systems Design: BIM facilitates seamless integration of various EV components, from batteries and motors to power electronics and software. This holistic approach optimizes performance, reduces complexity, and ensures optimal system compatibility.

• Enhanced Collaboration: BIM serves as a central hub for all stakeholders, from designers and engineers to manufacturers and suppliers. This real-time data sharing fosters seamless collaboration, improves communication, and minimizes errors.

2. Optimized Manufacturing:

• Digital Twins: BIM creates digital twins of EV production lines, simulating production processes and identifying potential bottlenecks or inefficiencies before they occur. This allows for proactive optimization of manufacturing processes, leading to increased efficiency and reduced waste.

• Robotic Integration: BIM data can be directly used to program robots involved in EV assembly, ensuring precise and consistent execution of tasks. This reduces human error and improves overall production quality.

• Predictive Maintenance: BIM enables real-time monitoring of EV production equipment, predicting potential failures and scheduling maintenance proactively. This minimizes downtime, increases production uptime, and reduces maintenance costs.

3. Sustainability Across the Value Chain:

• Material Optimization: BIM facilitates the selection of sustainable materials and minimizes waste during production. Additionally, it allows for life-cycle analysis, optimizing material choices for long-term sustainability.

• Energy-Efficient Manufacturing: BIM can be used to design and optimize energy-efficient production facilities, reducing the environmental footprint of EV manufacturing.

• Circular Economy: BIM supports the development of a circular economy for EVs by tracking materials and components throughout their lifecycle, facilitating recycling and reuse.

Challenges and Considerations in Implementing BIM for Electric Vehicle Development

While the benefits of using BIM in electric vehicle development are significant, several challenges and considerations must be addressed to ensure successful implementation:

Technological Infrastructure:

Adopting BIM requires robust technological infrastructure, including powerful hardware, software licenses, and high-speed internet connectivity. Companies must invest in the necessary technology to support BIM workflows, which may pose challenges for smaller manufacturers with limited resources.

Training and Skill Development:

The successful implementation of BIM relies on the expertise of personnel involved in the design and manufacturing processes. Companies need to invest in training programs to ensure that their teams are proficient in using BIM tools effectively. This may involve up skilling existing staff or hiring professionals with BIM expertise.

Data Security and Privacy:

BIM involves the creation and management of extensive datasets that may include sensitive information about designs, manufacturing processes, and supply chain details. Ensuring the security and privacy of this data is paramount, requiring robust cyber security measures and adherence to data protection regulations.

Interoperability Challenges:

The interoperability of BIM tools with other software applications used in the automotive industry can be a challenge. Compatibility issues between different software platforms may arise, necessitating seamless integration or the use of standardized file formats to ensure data exchange between systems.

Cost Considerations:

Implementing BIM involves initial costs related to software licenses, training, and technological infrastructure. While the long-term benefits are substantial, companies must carefully evaluate the upfront investment required and weigh it against the expected returns and efficiency gains.

AI and Machine Learning Integration:

The integration of artificial intelligence (AI) and machine learning (ML) with BIM holds the potential to further enhance the design and development of electric vehicles. Advanced algorithms can analyze vast datasets generated by BIM, providing insights into performance optimization, predictive maintenance, and energy efficiency. This synergy between BIM and AI can lead to more intelligent and adaptive electric vehicle systems.

Smart Manufacturing and Industry 4.0:

BIM aligns seamlessly with the principles of Industry 4.0, where smart manufacturing and the Internet of Things (IoT) play a central role. The digital twin concept, enabled by BIM, can be extended to the manufacturing process, creating a smart factory environment. Real-time data from production lines, IoT sensors, and BIM models can be leveraged to optimize manufacturing workflows, reduce waste, and improve overall efficiency.

Circular Economy Practices:

BIM's lifecycle management capabilities align with the principles of the circular economy, where products are designed for longevity, reuse, and recycling. In the context of electric vehicles, BIM can contribute to the development of vehicles that are easier to disassemble and recycle at the end of their life. This approach supports sustainability goals and reduces the environmental impact of electric vehicle manufacturing.

Urban Planning and EV Infrastructure:

Beyond the manufacturing process, BIM can play a crucial role in urban planning for the integration of electric vehicles into city landscapes. BIM models can be used to design and optimize EV charging infrastructure, predict traffic patterns, and plan for sustainable urban mobility. This holistic approach ensures that the benefits of electric vehicles extend beyond the vehicle itself to the entire urban ecosystem.

Regulatory Compliance and Certification:

BIM's ability to generate accurate and comprehensive data makes it a valuable tool for regulatory compliance and certification processes. As governments worldwide implement regulations and standards for electric vehicles, BIM can streamline the documentation and verification required for compliance. This ensures that electric vehicles meet safety, environmental, and performance standards.

Beyond the Hype: Real-world Examples of BIM in Action

Leading EV manufacturers like Tesla, BMW, and Volkswagen are already reaping the benefits of BIM implementation. Tesla's Gigafactory, for example, leverages BIM to optimize its production lines, resulting in significant efficiency gains and cost reductions. BMW utilizes BIM to enhance collaboration between its design and manufacturing teams, leading to faster and more efficient EV development.

Real-World Application: Tesla's Use of BIM in EV Manufacturing

Tesla, a pioneer in the electric vehicle industry, has embraced BIM as a central component of its manufacturing processes. The company utilizes BIM tools not only for the design and development of electric vehicles but also for the construction of its Gigafactories. The Gigafactory concept, which integrates manufacturing, energy storage, and renewable energy production, relies on BIM to create a digital twin of the entire facility.

Integrated Facility Design:

Tesla's Gigafactories are designed with an integrated approach, where BIM serves as the foundation for creating a comprehensive digital model of the facility. This includes the layout of production lines, machinery placement, and the integration of renewable energy solutions. The use of BIM ensures that the facility is optimized for efficiency and sustainability.

To get online demonstration, watch the following video tutorial.

Video Source: MicroCAD Training & Consulting

Supply Chain Integration:

Tesla leverages BIM to integrate its supply chain into the digital model. This includes tracking the flow of raw materials, components, and finished products throughout the manufacturing process. The seamless integration of the supply chain through BIM contributes to Tesla's ability to scale production and meet the growing demand for electric vehicles.

Virtual Prototyping and Testing:

Tesla utilizes BIM for virtual prototyping and testing of components and systems within its electric vehicles. This approach enables the company to iterate designs quickly, identify potential issues, and optimize performance without the need for extensive physical prototyping. The result is a streamlined development process and a faster time-to-market for new vehicle models.

Conclusion

By harnessing the power of BIM, the EV industry can accelerate its journey towards a sustainable future. From streamlined design and optimized manufacturing to enhanced collaboration and reduced environmental impact, BIM offers a roadmap for creating cleaner, more efficient, and ultimately, more affordable EVs. As the world transitions towards a brighter, electric future, BIM stands poised to be the invisible hand guiding us towards a sustainable and electrifying journey.

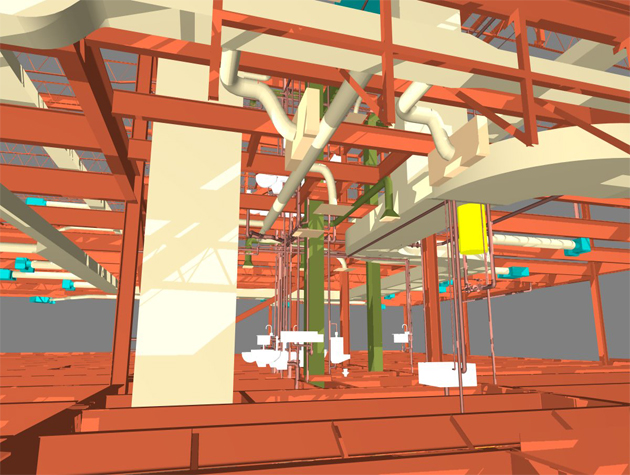

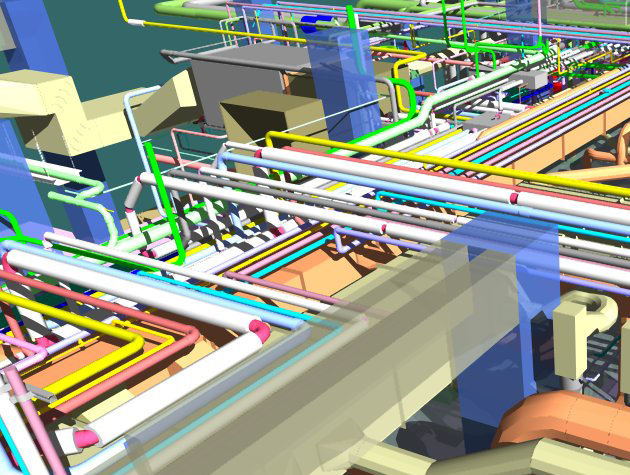

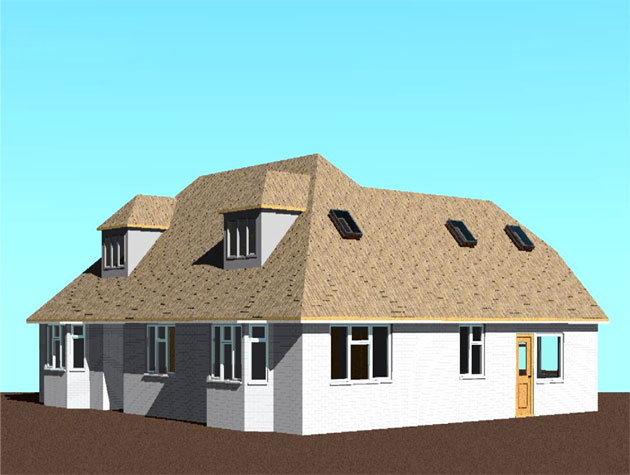

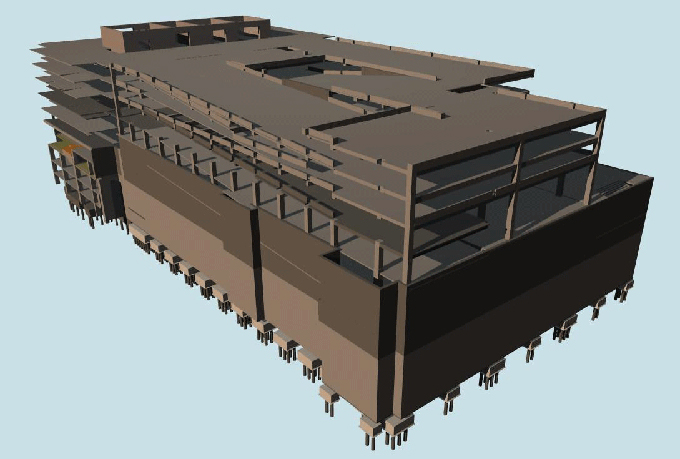

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !