What Businesses should know about 3D printing for Product Design?

Tweet

In addition to providing a more effective and cost effective way to create and iterate prototypes, 3D printing, and prototyping have revolutionized product design. The prototyping process has traditionally been time consuming and expensive, but additive manufacturing professionals have lately been using methods such as 3D printing to decrease the time & cost.

3D printing creates physical objects from digital designs using materials like plastics, metals, and composite filaments. Rapid prototyping is possible with the technology. Functional prototypes can be manufactured in-house with high end 3D printers like SLA and SLS. Small businesses may find it difficult to afford advanced 3D printers.

Materials for 3D Printing

Alternatives include using specialized 3D printing services, which offer a variety of materials at various prices. Materials such as resin or nylon are affordable options, while stainless steel is a premium metal material. Material weights and volumes as well as design complexity and size affect the cost. Companies may access various material options, obtain guidance on the best printing technique, and produce high quality prototypes without investing in expensive equipment through 3D printing services.

Merits of 3D Printing

Prototypes are built from basic shapes to confirm product dimensions and validate ideas. The DFM team progressively creates more complex models and experiments through multiple stages once approving the initial concept. During the final stages of development, the most promising design option is refined and improved.

A functional prototype can be manufactured using high end 3D printers like SLA and SLS. In addition, it saves both time and money since the process is done in-house.

Multi Component Design

A 3D printer can produce intricate and complex mechanical parts, even though it is most commonly used for proof of concept prototypes. Designers can achieve aesthetics and functionality close to final products by using individual filaments like metal or reinforced plastic.

High Fidelity Models

It is possible to prototype a product using only one 3D printer during the whole prototyping process. It is possible for designers to create a variety of different types of prototypes, from simple block models to high fidelity functional beta models.

Speed

It is the speed of the technology that distinguishes it from all the other advantages. During the early phase of product design and prototyping, 3D printing is a vital component of manufacturing proof of concept and getting quick feedback. Designers can refine and adjust the approach quickly using the printed model, even if it is not always functional.

3D Printing Applications

According to its definition, additive manufacturing is a fabrication technique in which a material is added, often layer by layer, until the required shape is obtained. Depending on the degree of accuracy and specificity required, there are various types.

Fused Deposition Modeling

The most cost effective choice is a 3D printer using fused deposition modeling technology. It builds up the shape layer by layer by extruding thermoplastic filaments that have been heated to the point of melting. Home usage of a fused deposition modeling 3D printer is acceptable.

Stereo lithography

A stereo lithography 3D printer helps produce the desired shape using liquid resin, unlike fused deposition modeling. Each printed layer will become harder under UV light until the prototype is finished. Although the cost is higher than fused deposition modeling, the outcome is significantly more precise. A plastic model with high resolution works best for prototyping.

Selective Laser Sintering

3D printers use powdered materials for their filament. The printed object is sintered layer by layer to create a solid model. Richly funded businesses frequently utilize SLS, which is more expensive than stereo lithography and fused deposition modeling to print high quality product design prototypes.

3D Printing Services

Services

Although purchasing a sophisticated 3D printer can be expensive for small firms, it is not the only additive manufacturing alternative available. There are many skilled prototype designers in the rapid prototyping sector who are prepared to meet your prototyping needs.

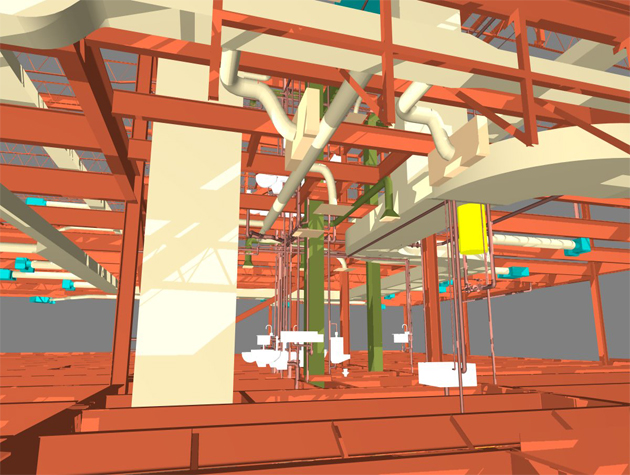

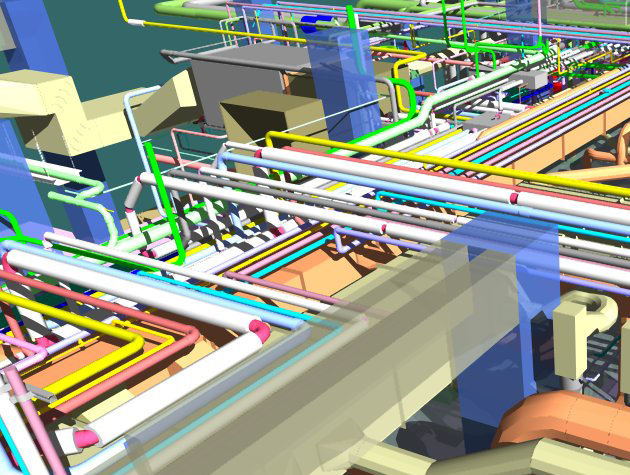

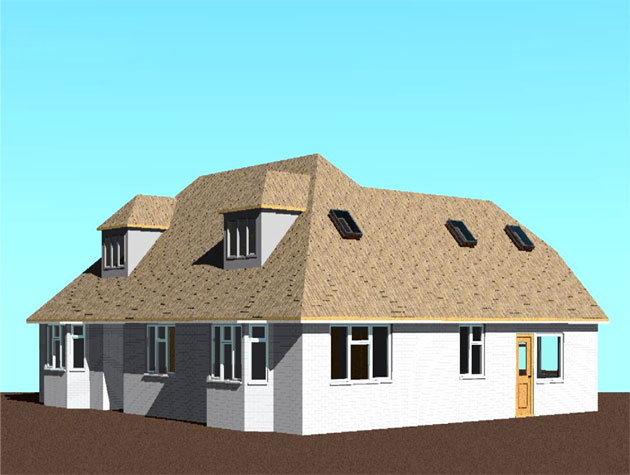

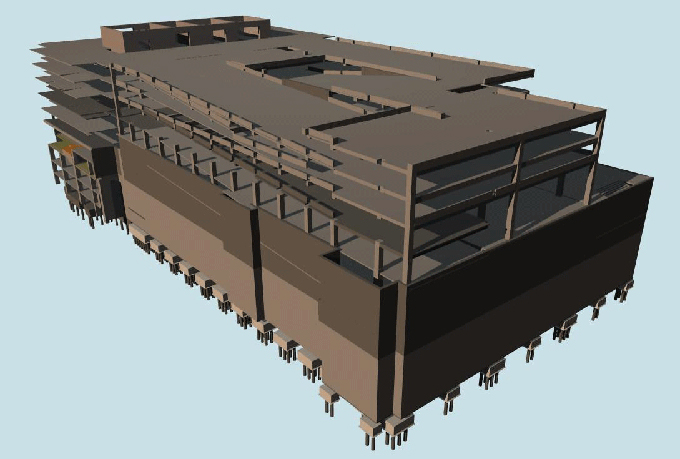

Although many prototyping designers offer a variety of services, including product designs, some specialize in architectural designs. They are small scale factories that print actual prototypes rather than manufacturers in the usual meaning of the word. The fundamental procedure is straightforward: you give the CAD file, and it is created.

Quality Control

The majority of 3D printing companies will produce the prototype which means they will complete your order and send the model to you. As long as you know what to anticipate in terms of quality, it is acceptable. The best course of action is to seek out a seasoned specialist in 3D print design who can walk you through the procedure and evaluate the CAD file. They will suggest the best printing method based on the analysis to get the desired shape.

Cost

One can investigate a variety of material possibilities using 3D printing services, each with a different price. Affordable options include nylon or standard resin, which normally cost between $20 and $30. Premium metal materials, such as stainless steel, are more expensive and typically cost around $900. The complexity of the design and the planned delivery schedule, in addition to the choice of materials, influence the project's final cost.

To get online demonstration, watch the following video tutorial.

Video Source: Proto3000

The cost of 3D printing materials is commonly determined by multiplying the weight or volume of the material used for a particular 3D print by the cost per unit of material. For instance, the predicted material consumption would be multiplied by the price per kilograms or per cubic centimeter of the material to get the cost of a 3D printed model.

Wrapping it Up

The most popular additive manufacturing method, while there are many others, is 3D printing design services. As the name suggests, technology makes an imagined design into a real thing. A digital fabrication technique called 3D printing uses materials like metal and plastic. The printing procedure can take hours, depending on the design's complexity, although it is still quicker than other options. Durable nylon, acrylonitrile butadiene styrene, powder metals, and polylactic acid are a few common types of filament.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !