7 Reasons to create 3D Printed Prototypes for your company

Tweet

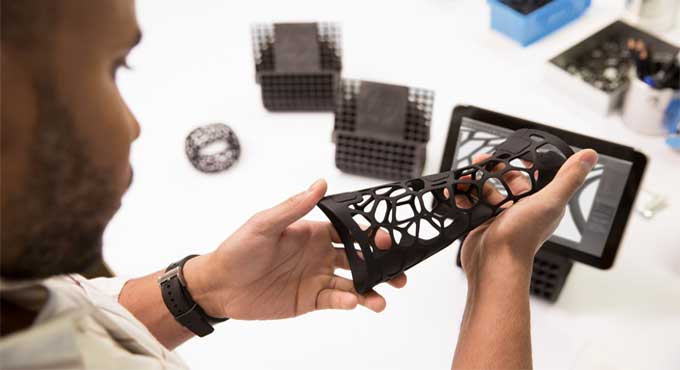

If you are looking for a better method of prototyping, 3D printing is the answer. A 3D printing design service is one of the most advanced additive technologies available today, providing high precision levels when developing your product prototype. In the list below, you will find some compelling reasons why 3D printing is a wise choice for prototypes of consumer products.

Competitive Edge

Prototypes made from 3D printing are also ideal for showing potential customers how your product idea will function in real life and show them in 3D. Companies can now cut the prototyping lifecycle short and present quality prototypes to clients and other stakeholders in less time thanks to the efficiency and speed of 3D printing.

Your clients are better able to understand what you can offer them when they see your product represented in the real world. Due to this, 3D printed prototypes do not risk losing important information or communication. These models can also be used to get feedback from investors and customers through marketing testing. You have an advantage over your competitors when you combine all of these factors.

Material Waste Reduction

In addition to sustainability, 3D-printed prototypes are a great option for your company. When carving prototypes from one block of material, subtractive methods waste a lot of raw materials. As for 3D printing, it is an additive technology that eliminates material waste by using only the quantity of material needed to produce the prototype. Furthermore, 3D printing materials are recyclable and have a low environmental impact.

Cost Reduction

3D printing shines during the prototype development stage when cost is a major concern for companies. Materials, machine operations, and transportation costs can all be reduced through 3D printing.

Traveling Cost

In addition to using less power than heavy machinery, 3D printers also cut costs significantly.

In terms of travel costs, 3D printing manufacturing services simplify the prototype production process from start to finish in one location. As a result, they do not have to be moved around several locations. Shipping costs are significantly reduced as a result.

Labor Cost

Due to its low supervision requirement, 3D printing reduces labor costs significantly compared to traditional machines. While prototyping costs can add up for a variety of reasons, labor is the biggest factor. In most cases, a single technician is required to turn on the machine and load the design for 3D printing.

Machine Cost

It provides significant savings compared to injection molding or machining, which require expensive tools and extensive setup. It is usually costly and challenging to manufacture complex geometries and interlocking features using traditional manufacturing processes. The use of 3D printing can simplify the process of creating these designs, which can lead to greater design possibilities and innovation.

Variety of Material Applications

The rapid adoption and popularity of 3D printed prototypes has increased the number of filament options for 3D printers. Companies can experiment with various materials suitable for prototyping through these numerous options, giving them a greater level of customization and freedom.

In 3D printing, you can work with a wide variety of materials and finish your prototype with a clear coat, paint, or even both. An effective prototype should have finishes and materials that are close to your expected end product. 3D printing is most commonly done with the following materials.

Risk Reduction during Manufacturing

It is possible to develop & test prototypes for a lower cost using 3D printing. As a result, it reduces a large portion of the financial risk associated with launching a new product. It is possible to make changes to designs and directions quickly.

When you are confident that your choices are right, then the prototype artist will develop several prototypes with slight differences. As a result, the trial & error process is more accessible than ever to 3D printing.

Companies can also use 3D printing to verify their product prototypes before they begin manufacturing. You can also present proof of concept samples to your stakeholders using 3D printing services. After seeing and touching your product idea, they will make a decision immediately.

Faster Method

A 3D printer uses CAD or computer aided design files as instructions for printing. When it comes to setting up a 3D printer, very little is required. Furthermore, conventional subtractive processes would require custom tools for your sample or prototype.

Depending on the size and complexity of the work-piece, the entire printing process will probably take a few hours. The shortened process allows you to move from concept to prototype to testing faster. In the past few years, the range of materials used by 3D product rendering companies for 3D printers has grown considerably.

Materials for prototypes are generally similar to those for final products. You can quickly modify your prototype and print it again if you discover adjustments that need to be made after testing it.

Helps in A/B Testing

The purpose of prototyping is to test several concepts and identify the one that meets all of your expectations. Traditional prototyping techniques take significantly longer. It takes a significant amount of time to A/B test a prototype using conventional methods from the point of creation to the point of polishing.

To get online demonstration, watch the following video tutorial.

Video Source: Mercedes-AMG Petronas Formula One Team

A 3D printer enables rapid testing of several prototypes within a short period of time. In just a few short minutes, the CAD drafting professional can create several variants of the original prototype of your product based on the changes made to the CAD file.

Wrapping it Up

By contrast, 3D printing is a subtractive manufacturing process, where bits of material are removed from a big piece to achieve the desired shape and size. Layers of material are added to the computer file one after another by the 3D printer. If you have more extensive production runs, 3D printing can be extremely time consuming.

It offers incredible advantages over injection molding, casting, and CNC machining when it comes to prototyping. The use of 3D printing services can help you save money by reducing the time it takes to complete the design, testing, and production.

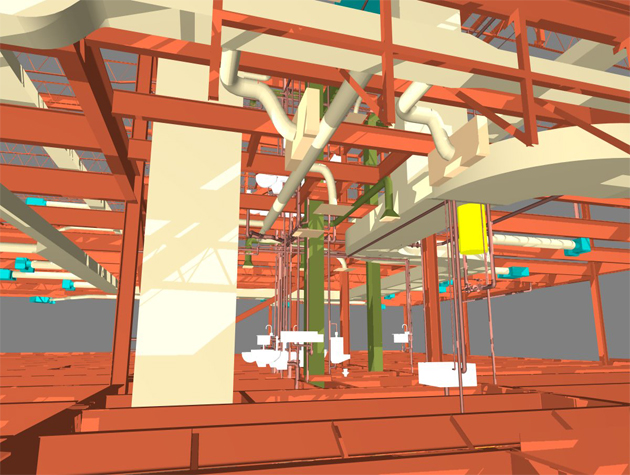

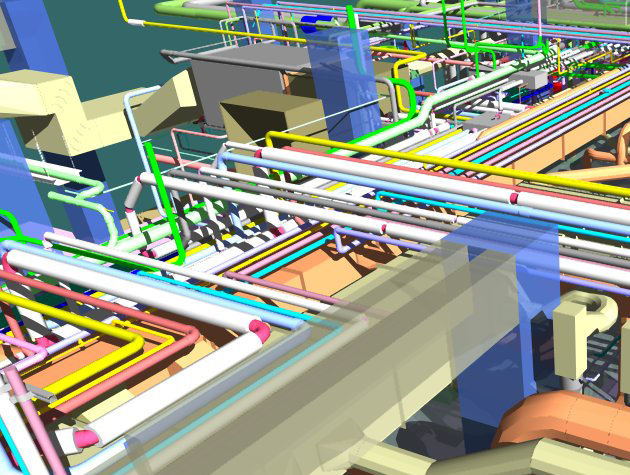

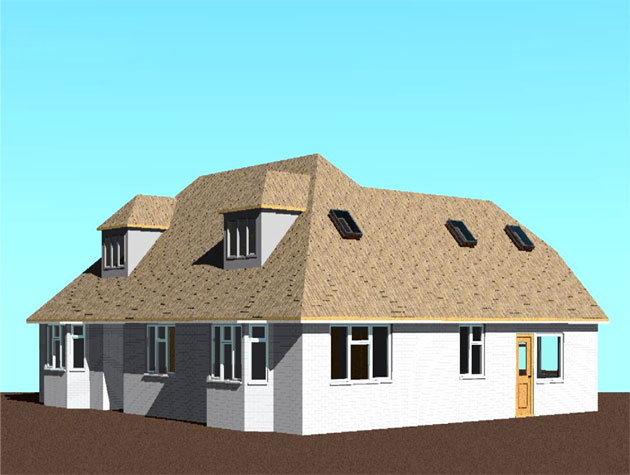

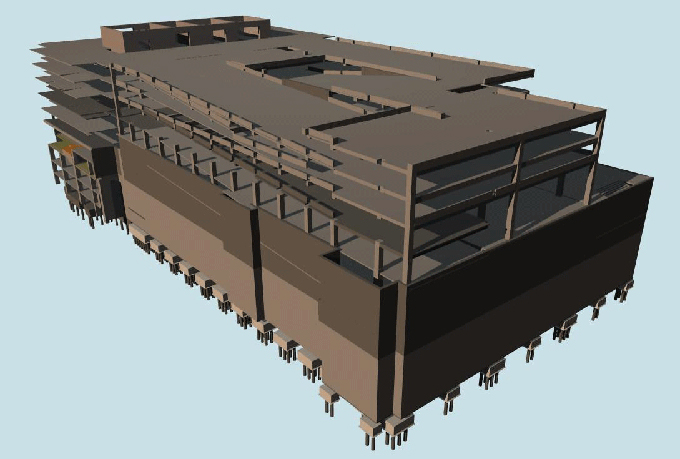

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !